FEEDBACK

Fatigue, rosters and absence management

Pressure on crews and scheduling stresses caused by sub-optimal planning and operations

One of the facets of recent roster and fatigue reporting to CHIRP has involved the employment of Controlled Rest (CR) by Flight Crew, also known as ‘in-seat napping’. We’ve also received a number of reports from Cabin Crew indicating that they either aren’t aware of the regimes for employment of CR, or aren’t being properly briefed by Flight Crew when they take advantage of it.

Because CR might not be achievable by an individual for personal physiological or circadian rhythm reasons, CHIRP doesn’t condone it being relied on in rostering schedules. However, it seems that it’s becoming increasingly normal practice for crews to employ CR for significant portions of the cruise phase for some sectors to mitigate increasingly punishing rosters or long flights that span the WOCL (Window Of Circadian Low) and so I thought we might add our thoughts to the debate.

Fundamentally, CR was originally intended only to be used in unforeseen circumstances to mitigate fatigue on long overnight sectors. Its use is sensible because it helps ensure that crews are at the top of their game when it comes to the more complex parts of the flight (i.e. descent, marshalling to the approach and landing), but crews should bear in mind that during the CR period, the aircraft is essentially being operated by a single pilot and so it should not be employed if high-workload activities or complex tasks such as ATC communication, readback or re-routing might be anticipated.

The original intention for the use of CR was that it would be used once in a flight but it is now becoming common practice to use it multiple times because rosters are now more intense and sectors are getting longer. Although CHIRP acknowledges that multiple use of CR during a flight is acceptable (as long as it is used properly), it must be carefully planned not only to ensure that too much sleep is not taken in one go (which, despite the temptation to sleep for extended periods, can result in increased drowsiness on waking), but also so that sufficient recovery time from the nap is factored in so that individuals are suitably alert and free from ‘sleep inertia’ before demanding high-workload tasks are performed.

Outlined in GM1 CAT.OP.MPA.210, the current inherited EASA FTL regulations are not particularly helpful in respect of CR, not least because they’re only guidance and not rules per se. As a result, the employment of CR is left to the vagaries of company operations manuals, and CHIRP’s view is that there is room for something more definitive within the regulatory document set. We note that the CAA have commenced an overall review of FTL regulations and we strongly support the inclusion of defined limits on the use of CR within this review. This would also usefully consider the long-term medical implications of fatigue and ‘napping’; as the workforce ages, people cope less well with fatigue and disruption to their circadian rhythm, so this should also be considered in fatigue management terms. The review should also consider the introduction of standardised ways of measuring alertness for fatiguing flights and after the use of CR so that comparative assessments of alertness can be made across the industry for sleepiness statistics.

Given the automatic nature of many modern aircraft, there is perhaps not the same level of mental activity on increasingly longer duration flights as there was in the past and so pilots’ potentially low alertness levels can also contribute to low arousal and the onset of sleepiness. There are a variety of sleepiness scales in use and, although many companies use the Karolinska Sleepiness Scale(KSS) to assess fatigue, its use is inconsistent in how they then deal with the high sleepiness scores that may be reported (see also CAA SRG Paper 2005/4 ‘Aircrew Fatigue: A Review of Research Undertaken on Behalf of the UK Civil Aviation Authority’). Ultimately, any regulations need to recognise that people have different tolerances, resilience and ability to cope with fatigue, and so it will be difficult to compose regulations that will cover all. But, fundamentally, the use of FRMS within companies should take the use of CR and sleepiness fully into account as part of the consideration of fatigue such that all sleepiness reports are incorporated, including the extremes of the scale, rather than discounting them as outliers and focusing on just the median reports for a particular trip-pairing/roster.

For completeness, the guidance for CR contained within GM1 CAT.OP.MPA.210 ‘Crew members at stations’ is reproduced at the end of this newsletter.

Steve Forward, Director Aviation

Reporting to CHIRP is easy by using either our website portal or our App (scan the appropriate QR code shown or search for ‘CHIRPAviation’ – ignoring the birdsong apps that may come up!). In our reporting portal you’ll be presented with a series of fields to complete, of which you fill in as much as you feel is relevant – not every field is mandatory, but the more information you can give us the better. Although you’ll need to enter your email address to get access to the portal, none of your details are shared outside CHIRP, and we have our own independent secure database and IT systems to ensure confidentiality.

![]()

Three paragraphs from a very comprehensive report and considerable further constructive details received by CHIRP indicate that the health of all engineering staff needs to be covered in greater depth. The conclusion determined at the end of the associated investigation was that the reporter’s employer was already following almost all of what the CAA suggested was best practice. The relevant paragraphs are:

In my role as a manager at [Operator], I am currently providing support to staff members facing various medical challenges, including sleep disorders, mental health issues, and other conditions. These licensed engineering personnel are currently on medical leave while undergoing treatment and following medical advice. However, I have observed a dearth of comprehensive medical guidance from the Civil Aviation Authority (CAA) in relation to Licensed Aircraft Engineers.

Previously, the Airworthiness Notice 47 “Licensed Aircraft Maintenance Engineers – Personal Responsibility When Medically Unfit or Under the Influence of Drink or Drugs” held relevance, but it has been succeeded by CAP562 Leaflet H-60, which addresses the same subject matter. Regrettably, the current document provides limited clarity for managers and supervisors regarding specific drugs or medical conditions necessitating heightened consideration. The statements contained therein are ambiguous, thereby leaving room for interpretation on the part of managers and the organization.

This lack of precise guidance from the CAA has the potential to enable licensed aircraft engineers to resume certification responsibilities and duties even when not fully fit for such roles, especially with the current resourcing levels in the industry. Occupational Health evaluations are conducted based on medical recommendations, but the awareness regarding individuals resuming certification privileges remains insufficient due to the dearth of actionable guidance. Notably, the CAA offers comprehensive advice for pilots, stipulating assessments by aviation medical examiners, details on which drugs both for physical and mental condition are not to be taken whilst exercising certification responsibilities. However, there is no analogous requirement for licensed aircraft engineers. The absence of guidelines pertaining to mental health, and how conditions like depression and anxiety may impact an individual’s capacity to fulfil certification responsibilities, needs reviewing.

CHIRP spoke with the CAA Medical Assessment Department about our concerns and they suggested that there were problems with introducing more comprehensive guidance because the working environment of engineers is so much more varied than pilots or ATCO’s. They also pointed out that the Health & Safety at Work Act sits above the CAA guidance and should be taken into account. As we all know, CAA activities are now largely based on risk and the relevant maintenance organisation’s Safety Management System.

In any organisation, the costs of adequate care and absence have to be balanced, but the use of either in-house or contracted Occupational Health professionals should be part of the Safety Management System, subject to being scrutinised for effectiveness and adapted as appropriate. An in-house Occupational Health professional is obviously more expensive but also likely more effective. Perhaps the cost would be offset by reduced lost man (person) hours. Qualified doctors can obtain a diploma after they have registered with the BMA as doctors in their applicable specialisation, which takes about a year. If, however, they make Occupational Health their specialisation, they have to do a four-year course. An Occupational Health professional could perhaps take five phone calls per day. On the other hand, they could take two and spend the rest of the day visiting the specific working environment of those two individuals, prior to their return to work. This scenario would apply to Line, Hangar, Workshops and all supporting activity (e.g. Planning, Maintrol, Supply Chain, Quality/ Compliance/ Safety and Administration.

Your Occupational Health professional should be au fait with both the environment and the tasks you are required to carry out, even if they were contracted in. Perhaps your Safety System needs not just an Aviation Occupational Health Professional but one that stays up-to-date and is competence assessed. Should they not be on the organisation’s list of authorised staff, along with the other background employees, Goods-In inspectors and planners etc? Do they have company-procedures refresher training? If an appropriate individual were to audit the Safety System in this subject, they would ask, has the Occupational Health professional had proper HF initial training? One would like to think they understand circadian rhythms, but do they know the 02:00 – 04:00 hour rule, could they name a handful of Critical Tasks? What does the word “Inspection” require of the inspector? What is their understanding of function/ operational tests? They would quickly need to familiarise themselves with the health and safety implications that we are all already familiar with such as industrial dermatitis implications, and are they likely to grasp other issues such as that of untied long hair that could lead to horrendous injury whether it was caught by a pillar drill, grinding wheel or an aircraft flap drive shaft? There would be a benefit to their working alongside of or holding the post of Health & Safety Officer. We should not blur the division of ‘Air Safety’ and ‘Health & Safety’ but a poor health & safety environment leads to distractions or hurrying the task in progress to name just two HF issues. Would an out-sourced Aviation Occupational Health Professional working from home be likely to raise a flag about a new risk in the Safety System? Would they even understand they are part of it?

Assuming every organisation has a Safety System (required by July 2024), the guidance in CAP562 Leaflet H-60 will surely be satisfactorily underpinned. However, we as a population both within and external to the aviation industry are becoming more aware of mental health and we all need to gain further understanding on how this affects individuals. A phased return to normal duties from a mental health perspective does become more complex than from a physical reason. Should it be a CAA regulatory requirement that our Aviation Occupational Health Professional has a good understanding of mental health issues? Should it not be a sub-subject in refresher safety training for us all anyway? A manager receiving a staff member returning to work after mental health issues may think that offering alternative duties would be sympathetic but the stress inflicted on the returnee by such a suggestion might re-raise stress levels far beyond limits. It is great that in organisations and amongst the population at large these conversations are taking place, and it is only by perpetrating this discussion (and perhaps including it in CAP562 Leaflet H-60 and Flight/Cabin Crew & ATC guidance) that we can gain greater understanding of mental health and as such improve safety and productivity.

Phil Young, Engineering Programme Manager

![]()

We value your opinion about our FEEDBACK newsletters and associated engagement methods, please spend a few minutes responding to 10 short questions about CHIRP Aviation FEEDBACK

Comment No1 – Legal vs Safe/Sensible I disagree with CHIRP’s assertion that Company responses of ‘it’s legal’ need to be framed within ‘it’s safe/sensible.’ The ANO does not permit a flight that is not safe/sensible. An operator of an aircraft must not cause or permit any person to fly as a member of its crew, who the operator knows or has reason to believe is suffering from or, having regard to the circumstances of the flight to be undertaken, is likely to suffer from such fatigue as may endanger the safety of the aircraft or of its occupants.

As aviators we spend our entire careers erring on the side of caution, anything that may endanger the safety of the aircraft is to be avoided. Rostering duties that are not safe/sensible that are likely to cause fatigue that may endanger the safety of the aircraft or of its occupants is prohibited by law. It is the responsibility of the CAA to ensure that there is no mis-match between schedule requirements and resource availability and the unsafe rosters that result. It really is that simple.

CHIRP Response: It seems to me that we agree. Our comment was very much framed with the intent that ‘it’s legal’ is not enough and that companies should be considering ‘it’s safe/sensible’ instead. Of course, one person’s ‘safe/sensible’ may well be different from another’s. Whilst no-one should fly when unsafe, FTL limits simply provide the framework for rostering and operations. For example, the use of Commander’s Discretion is not in itself unsafe if it is used in a considered manner with the Captain ensuring that all crew are able to operate safely, but it does allow captains to exceed the normal FTL limits. FTL limits are generic and cannot account for all circumstances and situations.

Our contention though is that frequent rostering of long duties can be fatiguing, and that rostering limits should only be approached with caution and in a managed way. Companies would of course comment that they do only approach them in a managed way, and if crews feel they are too fatigued to conduct a flight due to their own specific circumstances then they have a responsibility to declare themselves as such to ensure they do not endanger the aircraft or its occupants. As we all know, that is easier said than done, and so we end up with the circular argument where we say that some rosters can be fatiguing and the company saying that they are simply rostering within legal limits and if crews feel fatigued then they have a responsibility not to operate.

I’m no apologist for the CAA but they are sometimes caught in the middle. All they can do is ensure that the laws are followed. The Government sets those laws (basically carried over from our EASA days at present) but there are aspirations within the CAA to try to get them updated into something more relevant, and they are currently reviewing the FTL regulations with that in mind.

It is the responsibility of companies to ensure there is no mis-match between schedule requirements, resource availability and the rosters that result. The CAA have a responsibility to ensure that companies are operating within the law and to call them out when fatigue reporting indicates that things are not working. Hence the need to keep on reporting fatigue (even when it seems that nothing is being done as a result) – without data, nothing will change.

So, we share frustrations. Ultimately, the law probably needs to change to reflect modern post-pandemic reality. FTL will always be an emotive subject whereby setting generic limits is probably always doomed to fail but I am cautiously encouraged to hear the CAA talking about the need to review FTL and rostering and get the Government (DfT) to update the legal framework. However, I fear that with an election coming over the horizon, any legislative changes by DfT will be some way off.

-

ENG737

–

Incorrect use of MELIncorrect use of MELInitial Report

The flight crew arrived at the stand to find the aircraft only just arriving, having been towed over from the maintenance hangars. Crew boarded and commenced checks, shortly followed by line engineers, who were unhappy (but still helpful and working hard) at having had this aircraft dumped on them last minute. The engineers looked through the Tech Log and discovered a [system] deferred defect entry they weren’t happy about. The entry was made with a 10-day limitation, using MEL deferment authorisation.

The line engineer explained easily and in detail to the flight crew that this was not the correct MEL entry and that [component] was in fact a “no go” item. He showed on the system displays where the [component] was located and that how the procedure outlined in the MEL would be ineffective with engines running. He explained this would likely lead to a [Flight Deck] message either during take-off roll or in flight, which would then cause the aircraft to be AOG wherever it ended up. The engineers proceeded (under apparent pressure from engineering management over the telephone) to investigate the [defect], which had supposedly already been done in the hangar. They did not have the right steps equipment (due to the height needed to reach) and so had to make use of borescope equipment to try and establish [the source of the defect].

After some time, the engineers returned and explained the following to the flight crew.

They had confirmed the defect. They had looked up the information on this in the maintenance manual, where it explains that a specific piece of equipment is required to test the [system] to determine whether or not the [issue] is within limits for a dispatch or not. If out of limits, nil dispatch. If within limits, dispatch is allowed for a very limited number of sectors. They had then looked up whether [Operator] had that piece of testing equipment in stock, and they did not. Therefore, this required test cannot have been performed in the hangar, and the hangar had also clearly used the incorrect deferment authority and had not followed what the maintenance manual dictates, allows or recommends. This issue now went fully over to the senior engineering management and there was a period of time where everyone at the aircraft waited. The duty engineering manager arrived at the aircraft and requested the Captain operate the flight.

The Captain was aware of the information from the very experienced line engineer who had already said he would not want his signature stating this aircraft was airworthy. The Captain refused the manager’s request, who asked him once more, but then accepted the Captain’s decision. Service was then cancelled.

Too much pressure and [Aircraft Type] serviceability and parts availability is very concerning. So many ADDs, and worried how many are being correctly applied.

CHIRP Comment

The report was very comprehensive and detailed with the correct terminology and approved data references that had to be redacted for confidentiality reasons. Deviation from approved data references (AMM & MEL in this case) is a violation whichever way one considers it. The report investigation by the CAA focused on the poor decisions made in the hangar and the possibly perceived time pressure. Why does one fall into this trap? Is it because actual time pressure has now become so commonplace? Or, even though no management pressure was evident, perhaps peer pressure was at work? On the other hand, is perceived time pressure created or increased if colleagues seem to work at a slower rate than the Certifier/ Supervisor would like and therefore tries to compensate for? Happily, the Line Engineer did not line up the last hole in the cheese and, although the outcome was unfortunate, it was correct.

-

FC5292

–

RNP Approaches and mis-setting QNHRNP Approaches and mis-setting QNHInitial Report

Recent incidents have high-lighted a latent threat in RNP approaches, namely descending IMC with an incorrect QNH sidesteps most of the safeguards against CFIT. It is only a matter of time before there is a fatal accident. The old, bold pilot’s ruse of checking height/altitude against distance simply does not work. My company has been training to avoid this situation for a number of years – specifically comparing Rad Alt against distance. Good, but it doesn’t work if the terrain under the approach is not flat, and approach plates do not contain much, if any, information about the underlying terrain. I repeat that Altitude v Distance checks are not good enough. Is it really beyond the wit of man to provide, on every RNP approach plate, just one verified RADALT v Distance check, to give us old, bold pilots a fighting chance?

CHIRP Comment

Erroneous entry of QNH is a known problem with Baro-VNAV approaches within RNP procedures and the CAA recently published a video to highlight the issue, along with a note in April 2023 (SN-2023/003 ‘Risk of Controlled Flight into Terrain during 3D BARO-VNAV and 2D Approaches’) that also referred to the problem. ICAO has also published material on risks related to altimeter setting during BARO-VNAV approaches in their EUR OPS Bulletin 2023-001, which gives general and training recommendations. There is also an excellent YouTube video that discusses an incident at Paris Charles de Gaulle airport where a crew set the wrong QNH due to a number of factors and narrowly missed the ground.

Although CHIRP agrees that the introduction of a known radalt height at a specific range on the approach path is a good idea in theory, in practice there are a number of problems that might be encountered. If a specific point is chosen for the radalt ‘fix’ then that point would have to be protected from any subsequent erection of obstacles. Furthermore, it’s not clear who would be responsible for surveying each approach and protecting that location, would this be an Airport, ANSP or NAA responsibility? Chart providers rely on the AIP of the nation concerned to publish such data and so, ultimately, it becomes a national responsibility to survey and assure the data. Whilst there might be confidence that such surveys were robust in most countries, others might not be so comprehensive or regularly updated, and getting an ICAO agreement on responsibilities and data assurance would not be an easy prospect. Radalt does have its uses as a gross-error cross-check at a suitable part of an approach but, as the reporter comments, it must be recognised that terrain variations and the different geometric models in use in different countries mean that radalt is not always suitable as a definitive system to ensure that QNH has been set correctly.

In future, the use of QNH itself is under review as the provision of space-based GNSS altitude is being developed, but this does not solve the immediate problem. At present, the system relies on pilots making cross-checks to ensure that the correct QNH is set (such as pre-planning and corroboration by ATIS or transmissions to other aircraft). Digital ATIS upload is also available at some airports (although not widespread), and this can remove human input errors on the flight deck; although the cost to airports is quite high, if more of them were to install digital ATIS then this would provide a further safety enhancement.

Existing procedures, along with using radalt as a gross-error check, probably still offer the only realistic and robust way of ensuring that the correct QNH is set at present rather than waiting for ICAO to set standards and airports to survey, publish, certify and assure definitive radalt fix points on BARO-VNAV approaches.

-

FC5304

–

Flight Crew/Engineer interactionsFlight Crew/Engineer interactionsInitial Report

This report is published in précis in order to disidentify those involved.

Whilst conducting a pre-flight system check at [Base], it became apparent there was an issue with the aircraft similar to one that I had experienced with it before. Due to the engineers on my previous event in this aircraft being concerned by it I was equally concerned and decided to return to stand.

We were met by an engineer who I feel was putting undue commercial pressure on us to accept the aircraft. He was extremely rude and told us we were basically wrong and that there was no standby aircraft so we were cancelling a service because the aircraft was perfectly serviceable – all this whilst he was outside the aircraft on the headset. I told the engineer to come up and stairs were attached. He came into the flight deck and I demonstrated what I had experienced. Again, significant pressure was put on us to accept the aircraft but we AOG’d it, refused to accept it, and were moved to a standby aircraft which was available all morning. I was quite flustered by the whole event and it took a lot of effort to put it behind me. Several SOP slips were subsequently made and, although not unsafe, there was a noticeable impact on the efficient running of the flight due to the pressure being put on us by the engineer. I felt berated for doing my job as a ‘guardian of safety’ and ‘last line in the defence’ and I feel this individual had no thoughts of flight safety or of his actions.

CHIRP Comment

Firstly, CHIRP commends the reporter for doing the right thing; it is for the aircraft commander to decide whether or not they are happy with the state of the aircraft before they fly it and so they were absolutely right to reject pressure from the engineer to ignore their concerns: the old aviation maxim of ‘If there’s any doubt, there’s no doubt’ applies. Although the engineer may have considered that their professional abilities were being questioned and were probably under pressure themselves to meet scheduling requirements, advocating that the crew take the aircraft without any real investigation being conducted to determine whether or not there was an issue seems unwise at best. That the Captain had rejected the aircraft before for a similar issue should have raised red flags to everyone so it’s disappointing that more caution wasn’t exercised. Repetitive defects are a real cause for concern but, that being said, we should also be cautious about confirmation bias in potentially rejecting aircraft simply because we may have experienced problems with that airframe before.

On a Human Factors note, the fact that the crew were then flustered and made mistakes in the subsequent flight should be a warning to all of the negative results that confrontational engagements can have. Ground Handling and Maintenance personnel need to ensure that aircraft crews are not agitated by their interactions (and vice-versa) and, although it’s easier said than done, if unsettled and flustered by any event such as this, everyone needs to take a moment to recover their composure before carrying on with their tasks so that they are in the right frame of mind to avoid errors and mistakes.

As a matter of detail, when CHIRP spoke with the company concerned they said that subsequent investigations by the engineering team did result in a component change. Acknowledging this, they agreed that the main lesson from the report was to highlight the Human Factors connotations rather than dwell on the technical aspects.

-

FC5305

–

Runway closuresRunway closuresInitial Report

The runway at [Airport] is in desperate need of repairs, full of patches and bumps. In itself, this is little more than mildly annoying. The safety concern arises because these patches frequently breakup during normal operations resulting in immediate runway closure which typically lasts an hour or so while emergency repairs are undertaken. As an occasional occurrence, this would be no more than inconvenient to the diverting traffic. But it is not occasional, these unplanned runway closures are happening a few times a month and seem to be getting more frequent.

As pilots, we look at weather and NOTAMs to carry a safe yet cost-effective fuel load. We cannot plan for unexpected runway closures everyday, which is appropriate when these events are rare. They are no longer rare at [Airport]. Safety margins are eroded significantly when aircraft divert with low fuel and little time to prepare. Not to mention the disruption and delays caused to passengers and crew. Local crews are routinely carrying extra fuel to [Airport], unfamiliar crews have no warning of the problem so cannot learn.

I hope that CHIRP can access data from the airport on the frequency of these closures to assess the scale of the problem. There is concern among pilots that nothing is being done to address the problem and it would be helpful if CHIRP could establish if there is a plan is place.

Airport CommentWe understand the frustration that short notice closures cause flight crews and agree that over the summer period we experienced some breakups. The runway at [Airport] is an aged asset and is due for replacement in [the next couple of years], this programme is in-flight with Airline engagement already started. We have an extensive inspection regime that will identify any breakups quickly with our normal approach being to affect a temporary repair during the day (scheduled to minimise any disruption), followed by a permanent repair through the night.

At [Airport], we schedule two runway rehabilitation periods of engineering works every year, the first is pre-summer with the second executed in November. The scope of these works are determined by a full civil engineering assessment and this is also supported by our CAA Aerodrome Inspector. Since November’s rehab we have had 3 runway closures: 2 planned (outwith operational hours); and 1 unplanned (8 min closure and scheduled to avoid any impact to traffic). A NOTAM is a temporary measure which, given the data above, we don’t believe is warranted at this time, although we would remain open to the concept should the frequency of breakups increase to a point where regular and consistent diversions were required.

We have added this issue to the agenda of our Local Runway Safety Team meeting which has representation from all parties who use the runway including Airlines, Air Traffic, Operations etc and is a regular and well-attended forum with minutes being issued to all users regardless of attendance.

CHIRP Comment

CHIRP is grateful for the Airport’s pro-active response to our enquiries. It’s a tricky matter to decide when the frequency of closures might warrant a NOTAM but the key issue is to make sure that all airline users are aware of the problem so that they can take mitigations, which is what the intent of a NOTAM would be. Adding the issue to the agenda of the runway safety team forum meets that requirement to ensure that all users are made aware of the issue, and this represents a positive outcome from this report. -

FC5297/FC5298/FC5299/FC5308

–

Commander’s DiscretionCommander’s DiscretionInitial Report

CHIRP has received a number of reports in recent months regarding pressure to use Commander’s Discretion (CD); allegations of scheduled flight hours and turnround times being manipulated to induce crews to embark on outbound flights such that the real-world result was that return flights required the use of CD; requests to retrospectively submit CD reports where the system discovers that some crew members had exceeded FTL; and overly-robust engagements with management and Duty Pilots when captains have declined to use CD.

The nature of such reports make them largely impossible to disidentify when approaching the associated companies because they contain specific flight details, and many reporters have declined to agree to CHIRP doing so directly anyway for fear of negative consequences. On the other hand, most reporters have given permission for CHIRP to contact the CAA generically about these incidents and the CAA have conducted increased oversight of the companies involved to review their rostering and FTL management processes.

The CAA have concluded that awareness of the reasons and intent behind CD and its use is patchy, and that company processes to ensure sufficient stakeholder knowledge and thus appropriate CD utilisation are not as effective as they might be. A positive outcome was the recently published CAA Open Letter “in response to feedback via various safety forums that the use of Commander’s Discretion (‘CD’) is being inconsistently interpreted by industry stakeholders, leading to inappropriate application (or the perception of inappropriate application) of CD”. This is tangible evidence that the Regulator is aware of the increased use of CD and has engaged with companies to highlight that its use should only be in exceptional circumstances and for unforeseen situations.

CHIRP Comment

The use of CD is not unsafe in itself provided that a proper assessment of crew capabilities is made, but increasing numbers of CD reports are perhaps indicative of mounting pressures on crews from rostering and scheduling stresses caused by the system not operating as efficiently as it should. Ultimately it is the Captain’s responsibility as to whether CD is used, but all crew have a responsibility to make the Captain aware if they might exceed FTL and therefore require the use of CD (on the assumption that they are fit to continue to operate). But sometimes training in FTL is rudimentary (Cabin Crew may only get a single presentation during their training) and so levels of understanding might not be high for some. CHIRP thinks that company training about FTL in some airlines could be more extensive to ensure that all crew members are fully aware of FTL regulations and what CD means. There also needs to be robust processes in place to inform the Captain whether or not crew members might be approaching FTL limits. One would hope that company systems would not roster beyond FTL requirements, that manipulation of flight times was not a reality, and that systems were robust enough to identify when crew members might be approaching FTL limits in real time and warn them and their captains accordingly.

With regard to habitual use of CD, the CAA open letter is clear in its statements about the interpretation of ‘Unforeseen Circumstances’ as below:

CAA interpretation of ‘Unforeseen Circumstances’ (ORO.FTL.205(f))

Unforeseen circumstances are events on the day of operation that could not reasonably have been predicted and accommodated when the flight duty period was planned, such as adverse weather, equipment malfunction or air traffic delay. These events may result in necessary on-the-day operational adjustments that the operator could reasonably present to the operating Commander on or after report time. This is very similar to the ICAO definition.

There should be no expectation that Commanders should, or will, agree to extend the maximum planned flight duty period (as defined in the operator’s approved FTL scheme and CD Policy) for events that occur before the crew report for the affected FDP. The Commander must have access to the latest information, including the ability to determine crew condition, to exercise their judgement. This can only practically be assured at report time or during the FDP. Notwithstanding this, operators are expected to have a delay policy that is effective in protecting crew where possible from extended duties when delays are known about in sufficient time.

A crew member cannot commit to an extended maximum duty day (using the operators’ CD policy) prior to the Commander’s report.

The operational consequences of the Commander considering it inappropriate to extend the crew duty period after report, including the possibility of a night-stop down-route, has to be accepted and no commercial pressure can be applied at any stage.

CHIRP is heartened to see that at the end of their note on CD the CAA says that: “The CAA intends to review existing FTL regulation/amc/gm over the next 24 months as part of its continuous review programme, which will include those areas pertinent to CD”. We look forward to the outcome of their FTL review given the increasing number of fatigue reports that we’ve been receiving in the last few months during the post-COVID recovery of aviation.

-

FC5300

–

FDP start time later than arrival for workFDP start time later than arrival for workInitial Report

Definition of FDP commencing starts at gate area in airport rather than when crew member arrives at airport. It is not possible to be resident in the airport gate area so FDP is starting at a later than real start of duty. For those off-site parking who are unable to use public transport, a further mandatory bus journey compounds the issue. Airline manual makes it mandatory to report at the airport terminal commonly 30mins before FDP is begun. This could mean crew members are actually on duty beyond legal limits but it is not caught due to airline policy artificially commencing FDP later than reality.

CHIRP Comment

FDP starts from the point you report for any duty (duty being any activity done as a requirement for the company, including training, positioning or ground duties) and ends at engines off on the last sector. The overall relevant regulation is ORO.FTL.205 ‘Flight Duty Period (FDP)’. The location at which crews report will be specified within OM-A, and this is when FDP commences. The report location varies for individual airlines but may be before or after security, perhaps in the crew operations area, or another specified point. Regulations acknowledge that there will be commuting time to get from home to the report location and the associated start of FDP but this can differ depending on location and company agreements and is not specifically approved with the CAA as part of the AOC operating licence. GM1 ORO.FTL.205(a)(1) refers, but rather unhelpfully simply provides the bland statement that: “The operator should specify reporting times taking into account the type of operation, the size and type of aircraft and the reporting airport conditions.”

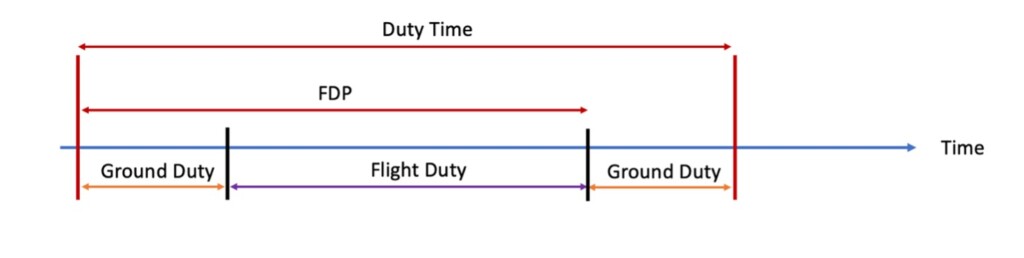

In all of this, it’s important to be aware of the distinction between FDP and FTL. FTL is solely about flight duties whereas FDP encompasses FTL and any other company duties before a flight. From ORO.FTL.105:

(10) ‘duty’ means any task that a crew member performs for the operator, including flight duty, administrative work, giving or receiving training and checking, positioning, and some elements of standby;

(11) ‘duty period’ means a period which starts when a crew member is required by an operator to report for or to commence a duty and ends when that person is free of all duties, including post-flight duty;

(12) ‘flight duty period (‘FDP’)’ means a period that commences when a crew member is required to report for duty, which includes a sector or a series of sectors, and finishes when the aircraft finally comes to rest and the engines are shut down, at the end of the last sector on which the crew member acts as an operating crew member;

(13) ‘flight time’ means, for aeroplanes, the time between an aircraft first moving from its parking place for the purpose of taking off until it comes to rest on the designated parking position and all engines or propellers are shut down;

(22) ‘rotation’ is a duty or a series of duties, including at least one flight duty, and rest periods out of home base, starting at home base and ending when returning to home base for a rest period where the operator is no longer responsible for the accommodation of the crew member;

Graphically, the following gives a generic representation as an example:

CHIRP has sympathy with the reporter because as operations have evolved (particularly since the COVID pandemic), some people who may have chosen to live at a certain distance from their base that worked in the past may now face difficulty in meeting current security and screening requirements etc that may significantly add to their commute-to-report time. There is no regulatory time specified for the commute and subsequent passage through the airport terminal to the report point for the obvious reason that every airport’s and operator’s circumstances are unique; but it is not legal for a company to require people to ‘report’ 30mins prior to FDP because, by definition, FDP starts at the time people are required to be at the report point or other location where they are required to commence company duties.

Although not now strictly applicable to UK AOCs, EASA has previously published a commentary about when FDP starts in relation to security checkpoints and report points in their document EASA FAQ n.135897 which is reproduced at the end of this newsletter. The response is clear that duty (and hence FDP) starts at the Report Point unless crew members are required to commence an activity such as passing through a security checkpoint (our underlining/highlighting in the attached text at the end of this newsletter). We have asked CAA whether they have a similar interpretation of when duty commences and they responded by saying that the journey time before report will be looked at as part of their ongoing overall FTL review this year which will consider the associated baseline assumptions and fatigue metrics.

Within this issue, it is often commented that regulations and company processes cannot factor in the nuances of every airport journey from arrival at the airport to the designated report point. Whilst we agree that generic regulations cannot be so specific, we do not think it is beyond companies to determine what the average expected time spent getting to the report point should be for each airport/report point combination and time of day. If companies chose to place the report point airside (either at a common reporting area or gate) then they should ensure that this is factored into the airport arrival-to-report journey duration. At the moment, companies are abrogating this responsibility to the crews who must individually calculate their optimum arrival time at the airport in order to meet their report time; CHIRP thinks that the companies should either make the report point the airport arrival time or should modify FDPs to account for the average time spent getting from airport arrival to the report point. On the other hand, the commute from home to the airport is the crews’ responsibility, it is for crews to ensure that they live at a suitable distance from their base airport so as to avoid prolonged commutes, with the exception that if the company subsequently changes their base location then a suitable mitigation may need to be agreed.

-

FC5301

–

Breakdown in CRMBreakdown in CRMInitial Report

I [the FO] arrived at the stand after being called from standby, went onboard the aircraft and couldn’t find the Captain who was in the toilets with their headphones listening to some music. The Captain didn’t speak to me and went downstairs with the same headphones on their ears. The Captain didn’t mention who would be PF or PM for the leg and so I followed them to ask for clarification, which was that I would be PM. After completing the turnaround, I went upstairs and sat in the cockpit waiting for the Captain to come onto the flight deck to perform the briefing.

On the next leg, it was my turn to be PF. Flight time was short so, once at cruising altitude and approaching Top Of Descent, I followed the SOP and decide to give control to the Captain so as to start preparing the aircraft for the approach and my brief. Whilst giving my brief, the Captain called for the descent checklist (this checklist should be completed after the briefing and when the PF has the flight controls back). I asked the Captain to stop and listen to the brief but they carried on. After performing my brief, I took back control and requested the descent checklist. Descent was commenced at a normal speed according to the SOPs but then the Captain decided to act as if they were PF and select a speed that I didn’t want to fly (320kt). When I refused the speed change and asked him to slow down because of turbulence building up and high ground near our destination, the Captain argued. I asked the Captain to let me fly a normal speed, but they refused and mentioned that they wanted to be on the ground as fast as possible. During the descent the Captain was changing vertical modes without asking me and we ended up high on the profile while approaching the destination. I wanted to slow down but the Captain refused, saying that we could make it but, on reaching 6nm, the aircraft was still fast (200kt instead of being at 160kt) and, whilst on the ILS, I started to use the speed brakes and asked him to select the gear down (to create drag so as to reduce the speed). The captain refused and told me that it was absolutely fine to be at 6nm with a speed of 200kt. In the end, the aircraft was fully configured and stabilised at the landing gate.

I thought about submitting an ASR about this flight but didn’t because I had been involved in an incident some weeks before which had undermined my confidence in the reporting system.

CHIRP Comment

This report describes some worrying CRM breaches that go counter to most accepted current practices. Bearing in mind that we only have one side of this story (the reporter did not respond to our request for us to contact the company), this report seems to indicate that, although we have come a long way in CRM terms over the years, there is still work to do. The Captain may well have had good reasons for expediting the approach, and was likely well-experienced in handling such, but there is no excuse for not communicating with the FO with more empathy and in a more collegiate manner throughout the 2 flights. FOs may well be inexperienced and rely on SOPs as the handrail that helps them build their skills: every Captain has a duty to nurture such FOs, even if they are not Training Captains, and they should adhere to SOPs unless there are sound reasons for deviating from them.

The reporter’s reluctance to submit an ASR is also a concern. They clearly had an unhappy experience from the previous incident and this looks like it caused them to question the ‘Just Culture’ of the company concerned. People may react in different ways to investigation outcomes, but it’s a hallmark of best-practice SMSs that they promote a Learning and Just Culture that gives employees confidence to report. Circumstances in this incident are difficult because there are overt criticisms of another crew member but without a report, no corrective measures will be taken if appropriate and that Captain may well not appreciate that their attitude and actions were not conducive to good CRM.

-

FC5312

–

Unrealistic Ground transportation timeUnrealistic Ground transportation timeInitial Report

I was given unrealistic ground transport times on an operating day multiple times. For example, I am based at [Airport 1] and was rostered to position to [Airport 2] with 2hrs allowed for the journey [using a popular satnav tool the driving time from [Airport 1] to [Airport 2] is quoted as typically being between 1hr40min to 2hr10min off peak and subject to further delays depending on traffic conditions]. How do I get through security, obtain food etc and still make the report time? The company response was that they “…cannot add more time to your ground transport as it will cause a FDT legality. We roster ground transport from airport to airport, you are free to leave earlier. [Airport 1] to [Airport 2] takes less than 2 hours”. Literally getting out of the car leaving it at the side of the road and running through security will take 2hrs30mins minimum. If the ground transport time is wrong then the duty is illegal isn’t it? Don’t we need more staff? Retain pilots? Keep the roster legal and mitigate fatigue?

They altered my block so I was flying a full block out of base at [Airport 2] but this wasn’t the action they wanted. They wanted me to travel in my own time in excess of the legal limits to operate at another base.

CHIRP Comment

CHIRP agrees that crews should not be pressured to try to achieve the unachievable and the company’s response was inappropriate. If it had been a taxi then perhaps it might have just about been feasible given that the reporter wouldn’t have to park, but it’s still tight. CHIRP commends the reporter for sticking to their guns and demanding a change to the roster, which worked out in the end but shouldn’t have been necessary. Our concern is that someone more biddable might have acquiesced and then would no doubt have been criticised for not making it on time. Unfortunately, the reporter didn’t get back to us to give permission to contact the company to get their perspective but we felt that the report was worthy of publication in a heavily disidentified form in order to highlight the issue to others. -

FC5290/FC5294

–

Inability to contact Ops/CrewingInability to contact Ops/CrewingInitial Report

FC5290 Report text: Crew, widely, are unable to get hold of our centralised support functions when it matters most. We’re left to fend for ourselves over and over again at the moment. No support, seems a safety issue.

FC5294 Report text: Company operations centre phone system is crumbling. The ops centre is severely understaffed and technically under-resourced. Routinely it takes several phone calls (my record this month is 17 attempted calls in a single 4hr period on-duty), the calls often usually go through with clear background noise and voices then immediately hang up (dropped calls by the system according to the Centre manager… the alternative is that staff are deliberately answering and immediately hanging up).

Due to the under-crewed operation, we’re regularly close to Max FDP, always on minimum rest, and delays (sometimes before report, sometimes after) mean we’re often beyond Max FDP, sometimes with Commander’s Discretion not available (delays known about before report, i.e. late inbound aircraft), sometimes with Commander’s Discretion not available due crew fitness or other reasons.

It can take hours to get hold of the company to either replace or compromise with crew on a favour-for-a-favour basis (although the company usually seem reluctant to do that). Crewing will usually want to get the flight out, even if it means not coming back. Ops usually want the first-wave protected and aircraft in-base the following day, not stuck down route because of FDP limits. It is becoming impossible to get hold of the company to get a decision whether to operate or cancel the flight. As a Captain, it is not our decision whether to operate a single flight or cancel, or attempt to operate return flights with a high risk of being stuck down route. There is also the added stress that if we attempt to make a decision such as to go, we then expose ourselves to a challenge of “you should have checked first”, or if we don’t go and spend hours trying to contact the company, the flights get cancelled and we’re told “you should have just gone”.

The company have had this reported numerous times, and nothing seems to change. They cannot handle minor disruption without things falling apart and crew are unable to delay off-duty times or get changed to legal duties when they check-out with an illegal rest period. If there was a major incident or something requiring informing the Duty Pilot, or even something that you wish to discuss operationally with them, it seems that is just impossible. The CAA need to investigate and apply pressure on the company to rectify this. One part of the solution is to employ more staff, you cannot have a single person dealing with [large numbers] of crew, and one person dealing with [numerous] aircraft when there are the levels of Eurocontrol sector disruption there were in 2023.

CHIRP Comment

It should go without saying that companies must have robust back-office resources and communication protocols for crews to be able to contact operations or crewing in a timely manner so that guidance or direction can be received on critical time-sensitive operational matters. Unfortunately, neither reporter responded to our requests to contact the company concerned and so we were unable to do so in accordance with our mandate to protect reporters identities. Given that the reporter states that this issue has been reported to the company numerous times without resolution, a cynic might say that there would likely be little to be gained even if we did engage with them. But we did pass on the reporters’ concerns to the CAA and ask that they investigate the company’s crew-to-operations communication protocols and resourcing. The CAA reported that they investigated this concern with the operator but, due to confidentiality requirements, they rarely give CHIRP detailed specifics about the outcomes of their engagement with companies other than a generic overview commenting that they have engaged on the matter. The CAA did inform CHIRP that the operator in question was aware of the limitations the current system had, and were investing in changes to address them. In this regard the CAA expects improvements and will look for evidence of effectiveness so hopefully something will have come from CAA’s engagement and our highlighting the issue.

-

FC5252/FC5293/FC5317

–

Sickness/Absence policiesSickness/Absence policiesInitial Report

FC5252 Report text: [Airline 1] sickness policy discourages crew calling sick.

FC5293 Report text: [Airline 2] sickness policy uses inappropriate rating of sickness. Crew are avoiding calling in sick. Rostering is inappropriate and due to disruption very often minimum rest. Often rostered into days off. Company assumes you will work into your day off. Crew are getting sick. Something needs to change. Even if the pressure to fly when sick is more perceived than actual, the bottom line is that when we cannot perform our duties and are not fit to fly we don’t fly, and this has seemed to escape the company.

Crew are on their knees, particularly at [Airport].

FC5317 Report text: In [Airline 1], flight crew sickness is managed as a disciplinary matter. Any flight crew who reports unfit to fly twice within 3 months enters the first stage of a disciplinary process, the last stage of which is dismissal. Further sickness pushes you further into the process.

The reverse side of my medical certificate reminds me of my obligations with regard to flying whilst unfit to do so, and my employer is very well aware of these obligations. The only possible outcome from managing sickness in this way is to frighten and intimidate crew into not reporting sick. We have a large number of new flight crew, as well as many who have recently returned from redundancy, all of whom are very anxious not to get into trouble at this stage in their employment, and sending messages informing them they are now in a disciplinary process is an extremely intimidating thing to do, and runs totally contrary to flight safety.

CHIRP Comment

Sickness/Absence policies seem to be another perennial topic that we keep banging the drum about. Results are patchy but we have had some successes in the past with companies altering their policies as a result of CHIRP activities. But the problem remains a focus for us and there is ongoing communication with [Airline 1] in particular to understand their sickness/absence management policy. There appear to be 3 elements to the debate:

1) the recognition that those who fly are different to those who do not because of the physiological aspects that some sicknesses (such as colds) can have on those who aviate and, as a result, are perhaps more prone to declaring sickness than their ground-based contemporaries;

2) many companies have onerous pay-policies in respect of sickness whereby they remove basic pay at an early stage of sickness and revert to only the paltry Statutory Sickness Pay (contrary to many other more enlightened companies who understand that sickness is a fact of life and continue to pay the basic salary as part of their covenant with their employees); and

3) whilst no doubt intending to be clear in their processes, some companies’ policies and communications for those who suffer repetitive sickness (such as multiple colds for example) can be perceived as intimidating and therefore appear to have the intention of discouraging those who are sick from removing themselves from duties, which not only puts them at risk of medical complications but also contravenes their duty not to operate if unfit to do so.

As in all things there is of course a balance, and companies must have appropriate processes to detect those who might abuse the system, but the emphasis in some companies seems to err more on the assumption of shirking rather than sickness. CHIRP has engaged many times with the CAA on this matter and we are encouraged to hear that there are ongoing debates within the industry Flight Operations Liaison Group (FOLG) ‘Well-being’ and ‘Fatigue’ forums to review best practice. What is required is a common and pragmatic approach to sickness/absence that recognises the unique situation that aviators are in, ensures that long-term or repetitive sufferers are able to receive appropriate attention and medical care as necessary, and removes the fear or stigma that might be attached to reporting sick on multiple occasions: all while giving companies the necessary tools to ensure that those who might take advantage of ‘pulling a sickie’ are not able to do so for long or recurrent periods.

-

FC5307

–

Fatigue vs sicknessFatigue vs sicknessInitial Report

Report is in précis due to identifying elements in the original.

I have recently needed to go fatigued, this is something I have never felt I needed to do before but, even though I have been flying commercially many years, never have I experienced more brutal rostering than at [Airline] after COVID. At [Airline], if you go sick they count all days off work (including days off) as total days of absence. However, with fatigue they only count 7 “duty” days towards fatigue, this is because they state that more than 7 days is most likely due to an “underlying” issue. This means that people feel pressured to return to operations earlier than they might otherwise after being fatigued because they don’t wish to enter the company’s long-term sickness processes. This penalises people because the company won’t class anything over 7 days as fatigue. You can’t class days fatigued as sick, you’re not sick, you’re simply following the rules by not operating in an unfit state.

CHIRP Comment

The issue of when long-term fatigue becomes sickness is a pertinent one that there’s no easy answer to; as far as we’re aware, there’s nothing written down that provides guidance as to where the dividing line is between being fatigued and being long-term sick. Science tells us that fatigue is long-term underlying exhaustion as opposed to simple tiredness but, whereas tiredness can be overcome by a few good nights’ sleep, there’s little scientific material about how long it might take to recover from fatigue. It doesn’t seem unreasonable that after a certain period, fatigue should be classed as ‘long-term sick’ because at some point medical intervention should be sought to address any underlying issues if relevant.

CHIRP approached the CAA for help and they told us that the FOLG ‘fitness to fly’ subgroup were debating this very issue and that it was recognised that companies needed some form of trigger for reclassifying fatigue as sickness so that other help mechanisms could be invoked that might not otherwise be available – companies have a duty to the fatigued person to recognise that they might be sick so that they could get the proper help. The thinking being that, as a practical measure, if someone was still fatigued after 7 days then they really ought to be seeking medical help and it did not seem unreasonable to change someone’s status from ‘fatigued’ to ‘sick’ so that underlying issues might be diagnosed by the AME and Occupational Health experts. However, they recognise that it’s not easy to cover all individual circumstances with blanket regulations or policies.

As an aside, one interesting employment aspect of this might be that if the company do declare you as long-term sick after being fatigued then there’s a good argument that the cause of the long-term sickness was the fatigue induced by the company and so they may have breached their Health & Safety obligations by causing you to become long-term sick due to the work environment. It’s uncertain how that would hold up legally, but perhaps companies should be careful what they wish for.

[Operator] Engineering management have in general (not referring to this event) always stated that the Captain has the final word whether to accept the aircraft or not. The task was poorly planned into the hangar and accepted by the team in the previous shift because neither the test kit was arranged nor the task changed for the replacement of the [Component]; additionally, a replacement [Component] had not been arranged. The LAE who dealt with the input had 3 aircraft to deal with and delivery on time was a prime consideration for him. The engineer did state that he was not put under any pressure from Engineering Management however. He did not raise any issues of missing test kit with the [Maintenance Control] office and proceeded to do a test by an alternate method which was not in the approved data. He recorded the rectification by raising an ADD without any approved data reference. The test kit required had been sent for calibration in the first half of 2022 and returned. It was awaiting paperwork confirmation. Correct planning would have made arrangements for a [defect] tester to be available. Note; [Operator] have put a series of mitigations in place to prevent this happing again and the CAA will review when this is complete.