The Charity

Aviation

Maritime

Sounds familiar?

Initial Report

Several brief reports containing subject matter that CHIRP continues to receive with monotonous regularity. Why do these incidents continue to occur? We are not describing any complicated situations – common sense and a little thought would go such a long way to eliminate these types of reports.

What the Reporter told us (1):

The fire alarm sounded, and all crew commenced mustering. Upon reaching the bridge, the master found that the electrician was testing the system, but the officer on watch had not made any public address announcement to inform the crew about this test. Quite apart from the false alarm, crewmembers could have been hurt by the automatic-closing accommodation doors.

What the Reporter told us (2):

Whilst transferring an electrical motor to the engine room by crane, it was noted that a non-certified wire sling was being used. The crane operator noticed an AB attempting to connect a hand-made sling for lowering the motor to the engine room. Work was suspended until a suitably certified sling was located.

What the Reporter told us (3):

Whilst undertaking purging operations to reduce H2S levels in cargo tanks, the bridge OOW saw an ER fitter on deck heading to a midship’s store. Being on deck during purging operations was prohibited due to the high concentration of H2S in the area. The fitter was instructed to clear the deck immediately.

What the Reporter told us (4):

A high-level alarm was activated in the engine room bilge. Whilst transferring the bilges to the bilge holding tank, the duty engineer noted a small amount of water leaking into the bilge well on a continuous basis. This was traced back to a water tap in the engineers’ changing room. The tap had been left partially open, presumably as a result of carelessness by an unknown party.

What the Reporter told us (5):

During routine chipping/maintenance of the MARPOL cargo drain line at the starboard manifold, an OS discovered a hole in the line from the manifold drip tray to the main line leading to 3S COT. The hole was not as a result of the current maintenance but seemed to be rather old, the result of a previous temporary repair, hidden and painted. The OS reported this to the Chief Officer who checked the drain line and asked the pumpman to remove it in order for a new one to be fitted.

What the Reporter told us (6):

On this vessel, the emergency fire pump must be continuously run during laden voyages to cool the main engine jacket. At 07:30 the engineer on duty found the emergency fire pump stopped. No one on the bridge or the engine control room could understand how or when the emergency fire pump stopped. As a direct consequence of the stoppage, the temperatures of the main engine were increasing and the engineer on duty reduced the RPM without informing the bridge. The vessel was due to arrive in port later that morning but the reduced RPM, which the bridge OOW was unaware of, caused a reduction in speed resulting in a delay to the port arrival.

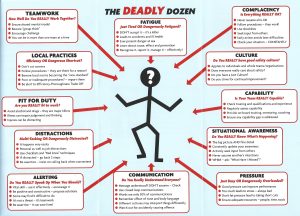

Human Element – The Deadly Dozen

CHIRP Comment:

CHIRP frequently highlights the importance of the Human Element in all aspects of shipboard operations and makes no apology for repeating the message. Reading the above reports there are several themes that are immediately apparent – primarily Communication! Communication! Communication! Work planning which was properly communicated would have gone a long way to preventing any of these reports becoming near misses. Other aspects of the Human Element that are missing in the reports above are situational awareness, culture, local practices and teamwork. It will be no surprise that CHIRP’s analysis of all reports received highlight these areas of the Human Element as the ones that consistently show failings. Overall the message is clear – Plan what you do, do what you plan, and record it.

Report Ends