FEEDBACK

Tired? Know your limits

All crew members should be aware of their maximum flight time limitations (Max FTLs) and check their rosters are compliant

This summer the volume of flights is returning to 2019 levels, but staffing issues and industrial action could cause another period of disruption. Cabin crew frequently report to CHIRP that they are approaching their maximum hours which leaves little flexibility in a busy roster. UK Retained Regulations (EU) AMC1 ORO.FTL.110 states:

‘Scheduling has an important impact on a crew member’s ability to sleep and to maintain a proper level of alertness. When developing a workable roster, the operator should strike a fair balance between the commercial needs and the capacity of individual crew members to work effectively’.

All crew members should be aware of their maximum flight time limitations (Max FTLs) and should check that their rosters are compliant. Each crew member is responsible for ensuring that these Max FTLs are not exceeded and for alerting their operator if they think this is likely to happen.

It is equally important that crew plan and utilise their rest periods at home and down route effectively. UK Retained Regulations (EU) ORO.FTL.115 Crew member Responsibilities states:

‘(b) make optimum use of the opportunities and facilities for rest provided and use rest periods properly’.

It can be challenging to maintain healthy sleep habits when working shifts, studies by NASA have found that short power naps can increase performance, vitality, and productivity. For information and advice on sleep please click on this link How to fall asleep faster and sleep better – Every Mind Matters – NHS (www.nhs.uk)

Who are CHIRP?

In light of the recent inflow of crew into the cabin crew community, I thought it would be useful to remind our readers who we are and why it is important to report to CHIRP.

CHIRP (Confidential Human-factors Incident Reporting Programme) provides confidential reporting for individuals in the aviation and maritime sectors. The CHIRP Aviation Programme team is made up of a small group of specialists with professional and technical expertise in aviation operations and Human Factors. More information can be found in the ‘About Us’ area of our website Aviation Programme – CHIRP

CHIRP is recognised by the UK State Safety Programme as the UK’s independent, confidential, voluntary reporting programme that provides an essential safety net for gathering reports that would otherwise have gone unwritten with associated safety problems not being reported, and for providing another way to promote change if necessary.

In order to promote the resolution of safety-related issues raised, we draw on the assistance and counsel of a wide range of independent experts and specialist bodies from across the spectrum of aviation through the Advisory Boards. There are four CHIRP Aviation Advisory Boards: Air Transport, Cabin Crew, Drones/UAS (Unmanned Aerial Systems) and General Aviation.

The majority of the Cabin Crew Advisory Board (CCAB) members work for airlines in safety / operational roles, but they participate in meetings as independent members largely to share their personal knowledge and expertise (not as representatives of their sponsoring organisations or employers). Information is provided to the Advisory Boards on a confidential basis, and all means of identifying the individual reporter are removed from reports prior to any discussion. The Board’s purpose is to provide guidance to the Cabin Crew Programme Manager on cabin crew reports that have been received through the programme and provide advice and information to be used in the CHIRP comments that are published in Cabin Crew FEEDBACK. Additionally, CCAB members can share generic learnings from CHIRP with their own operators for continuous improvement and to overall benefit safety in the UK commercial aviation sector.

The CHIRP CCAB, also includes independent operational flight crew, the UK Civil Aviation Authority (CAA), the UK Flight Safety Committee (UKFSC) and the trade union Unite. Details of the Cabin Crew Advisory Board can be found on the CHIRP website at Aviation Advisory Board Members – CHIRP

Why Report?

Things are unlikely to change unless reported (and the company is aware of it) – grumbles and moans during a chat in the galley rarely result in change so operators need to be advised of any safety issues in order to analyse, track trends and, if necessary, take appropriate action. Operator’s safety management systems (SMS) recognise a ‘Just Culture’ – A ‘Just Culture’ aims to encourage employees to openly and freely disclose crucial safety-related information and to encourage ongoing learning from past mistakes. Reporters are therefore always urged to voice their concerns to their operator in the first instance if they feel able to since this frequently leads to the quickest resolution. We can engage with operators and the regulator on your behalf if you wish to remain anonymous to them but always consider using the formal company reporting processes first.

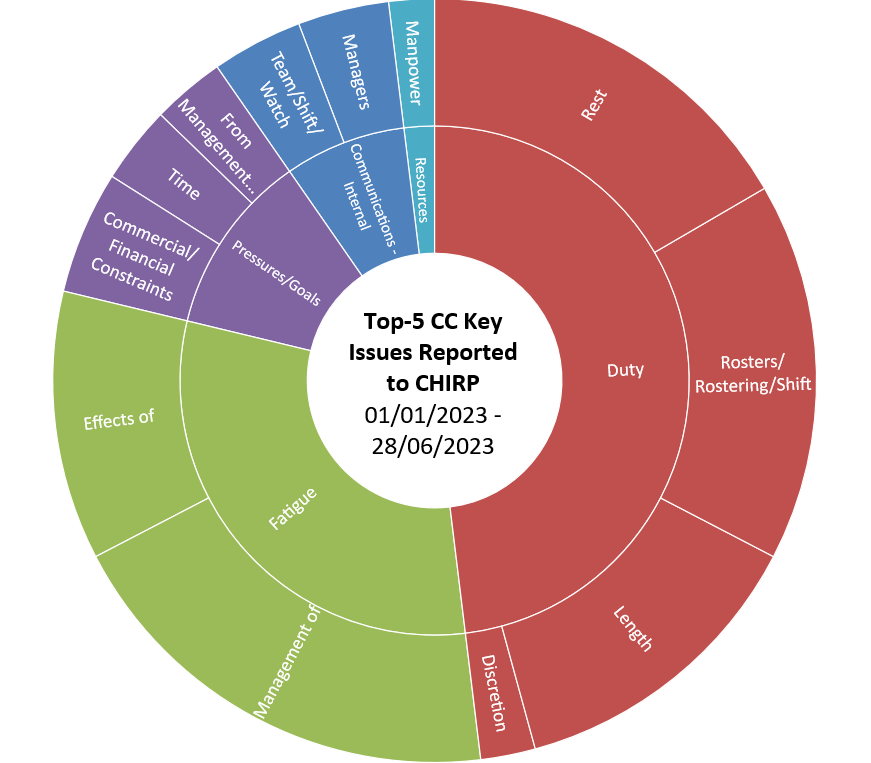

Cabin crew, primarily from UK operators, submit confidential safety-related reports on a variety of topics to CHIRP; key issues so far this year have been related to duty periods, fatigue and commercial pressure. CHIRP received 190 reports from cabin crew in the first half of 2023. The top-5 key issues from these reports are shown in the graphic (Duty, Fatigue, Pressures/Goals, Internal Communications and Resources/Manpower. These high-level Key Issues were further sub-classified into detailed factors as shown in the outer ring of the illustration.

Here at CHIRP we very much value your inputs and comments, positive or otherwise. We recognise that there is always room for improvement, and we want to ensure that we are giving you valuable content to support and enhance safety. Please do get in touch at mail@chirp.co.uk and let us know what you think about this edition, or anything else (that’s safety related).

The CHIRP Aviation Programme also provides a facility for confidential reporting of Bullying, Harassment, Discrimination and Victimisation (BHDV) where there is an identifiable safety-related concern. CHIRP has no specific expertise or resources to investigate BHDV reports. CHIRP’s role is to aggregate data to build a picture of the prevalence of BHDV in the aviation sector. See our BHDV page on the CHIRP website for further information. CHIRP’s role in reporting Bullying, Harassment, Discrimination and Victimisation (BHDV)

Jennifer Curran

Cabin Crew Programme Manager

-

CC6153

–

Evacuation AlarmEvacuation AlarmInitial Report

The Forward Attendant Panel (FAP) had been inoperative for 8 days, I was assured this is OK for up to 10 days, but unable to sound evacuation alarm from cabin either FAP or AAP (Additional Attendant Panel), also not able to use toilet lights or pax reading lights also unable to adjust cabin lighting for take-off landing in darkness.

CHIRP Comment

Manufacturers’ risk assessments determine what is and what isn’t a no-go item and these items are specified in the aircrafts’ Minimum Equipment List (MEL) . It is not ideal for aircraft to be dispatched with inoperative equipment, but such operations are permitted only as a result of careful analysis of each item to ensure that an acceptable level of safety is maintained. The Minimum Equipment List (MEL) also lists the equipment that may be temporarily inoperative, subject to certain conditions, at the commencement of a flight. In the event of any defects being notified or arising before take-off, the Commander must review them against the MEL to ensure the aircraft can still be safely dispatched.

Defects in the cabin are less than desirable especially when they impact the comfort of the passengers on board. If there is a defect in the cabin mitigations or alternative measures may be in place, for example, if the FAP is in-op (and there is no other method available) it is permissible not to dim the cabin lights for take-off and landing.

Regarding the evacuation alarm, if the this was suddenly in-op during the flight, and then in the event of an evacuation, what would you do? If a loud-hailer is available, use it. Otherwise, shout; while automation has many advantages, it shouldn’t always be relied upon. Alternative measures should be discussed with the crew during the briefing, if the defect only becomes apparent onboard, make sure you take the opportunity to address any alternative measures to aid your situational awareness.

-

CC6119

–

Contaminated waterContaminated waterInitial Report

Aircraft keeps being dispatched with contaminated water.

Advised not to use the water from G1, G2 & G4

Have to tell passengers not to clean their teeth with water out of the taps.

Crew are told to use anti-bac after washing their hands.

Advised we can serve hot drinks but we didn’t.

The aircraft conditions are also absolutely freezing as they have disabled the underfloor heating in galleys so we couldn’t warm up with a hot drink on a 9.5 hour flight.

Company CommentWe have not received any further reports internally concerning issues related to allegations of contaminated potable water, other than the issues raised in this report, which have also been raised separately via the Cabin Crew [Union] H&S Reps at their meeting.

As part of our water quality monitoring programme, [Contract Organisation] continue to monitor our potable water which includes regular audits and monthly potable water testing, this is managed via our Airports Business Area. ([Contract Organisation] also conduct our food safety audits at our catering units worldwide). Findings from this monitoring are reviewed each month at internal meetings and actions taken, this includes alerting the Engineering team should an aircraft require the water tank to be decontaminated. In the event that there are bowser issues and sufficient potable water cannot be uploaded or, alleged contamination (until testing has taken place), alternative measures are taken – this can include provision of bottled water to customers, suspension of hot beverages, antibacterial wipes/gel in LAVs and additional bottled water supplied to our crew.

We have reminded [The Trade Union] to encourage their members to continue to raise safety related ORs to ensure that we are able to monitor trends and take action in a timely manner. This also enables us to ensure our Airports and Engineering and Maintenance teams to take the necessary action (such as water treatment). [Element of Operators Defect Recording System] are in place to advise crew and engineering of what action they are required to take in regards to serving of water from the galleys – this information is also shared by the Senior Cabin Crew Member to the cabin crew at the briefing to ensure they are forewarned. It is also very important that cabin crew record any issues in the Cabin Defects Log or Tech Log, to ensure Engineering are aware after the flight has landed. In regard to the galley heated floor issues, the [scheduled] cabin activity will not comprise of any work on the galley floor heating. From a safety perspective, the decision was made to deactivate the floor heating system due to overheating.

CAA CommentHaving reviewed the internal safety and technical reports, there appears to be a very infrequent number. However, a report relating to the CHIRP occurrence has been identified. As a result of these infrequent reports, the operator does not see a systemic issue across their aircraft which can be narrowed down to a fleet, tail or station which is causing particular concern. The water is routinely tested and treated per their procedures.

CHIRP Comment

The lack of potable water will have been an inconvenience and extra burden on the crew. Sufficient bottled water should be loaded for passenger and crew use and hand gel made available. The legislation, ICAO, WHO, Guide to Hygiene and Sanitation in Aviation 2009. 2.1.5 Page 11, state that one use for potable water is emergency medical use.

This report has been ongoing since 18th October 2022 and a further communication in May 2023 recorded another contaminated aircraft. The Operator has reported that oversight, sampling and possible preventative action are still subject to review. It is unclear why the crew decided not to serve hot drinks as they had been advised that hot drinks could have been served and so be cautious about restricting yourself more than is required.

The floor heating seems to be an issue that is going to be around for some time and CHIRP has ascertained that not all operators of the same aircraft type have carried out a blanket deactivation of the galley floor system. Please continue to report regarding these issues via your operator as they are best placed to resolve your concerns.

-

CC6209

–

Too high a percentage of inexperienced crewToo high a percentage of inexperienced crewInitial Report

I checked in briefing a crew of 10 (11 including myself) – I was allocating positions in the economy cabin first as there was 3 crew (3 required) who were only trained in the economy service – during allocation it became aware that these 3 crew members were also on their first trips on long haul having only just joined the company. I considered it risky to have these inexperienced crew potentially on their own during the flight and also having to operate doors…a pair of doors was operated by two crew who were on their first trip.

The company service standard states that there should be no crew operate in either of the premium cabins if they haven’t done the respective courses.

I alerted our cabin crew managers to this dilemma and I was told that because more than 60% of the crew were experienced then it was “ legal”. This ignores the point entirely. The percentage of inexperience being made to operate in economy was 75%.

As the senior crew member I took it upon myself to move one crew member into a premium cabin (against the company’s service standards), but felt it necessary purely on a safety basis. I was confident with my experience I could coach and mentor this crew member to work the cabin appropriately.

Company CommentThe operations manual states that the SCCM must ensure that there is an even spread of experience between the front and rear of the aircraft for take-off and landing. This is also referenced in the briefing document issued to SCCMs regarding the ‘allocation of crew working positions’. Once in-flight, from a safety and service perspective, the SCCM is empowered to make a decision to allocate crew resource in the required cabin based on their assessment to meet the requirements of the flight, this includes during breaks if they are required. Newer crew colleagues may have joined the airline from another airline with previous premium cabin experience or they may have experience in the hospitality industry, together with ‘on the job’ coaching from the SCCM and experienced colleagues, they can deliver the service to the best of their ability. The even spread of experience must apply for take-off and landing only, for example a crew member could be seated at a door in the premium cabin and then work in the economy cabin. The reporter is encouraged to report their safety concerns following the internal safety reporting method.

CAA CommentRegulatory requirements state that some of the operating cabin crew should have more than three months operating experience. Three inexperienced cabin crew members of a total cabin crew complement of eleven is perfectly acceptable. Cabin service is not a consideration and on the reported flight it would have been appropriate for the SCCM to evenly distribute the experience throughout the aircraft.

The Operator has gone beyond the requirement. This is managed at planning stage and the system alerts when too many new crews are assigned to a flight.

CHIRP Comment

UK Retained Regulation (EU) AMC1 ORO.CC.100 states: ‘when scheduling cabin crew for a flight, the operator should establish procedures that take account of the experience of each cabin crew member. The procedures should specify that the required cabin crew includes some cabin crew members who have at least 3 months experience as an operating cabin crew member’.

Some operators stipulate that 50% of the cabin crew on board must have over 3 months experience, some operators do not.

From a safety perspective, experience should be distributed evenly throughout the aircraft and the SSCM did the correct thing in ensuring this was the case. Safety must come before service.

-

CC6263

–

Fatigue due to inadequate cabin crew rest provisionFatigue due to inadequate cabin crew rest provisionInitial Report

My operator operates aircraft with no cabin crew bunks. The provision for cabin crew rest is taken on aircraft jump seats that are located close to aircraft doors and in particular passenger aisle areas. This means that crew whilst taking rest are constantly disturbed, on my flight a passenger fell onto a crew member taking rest because the space between the passenger aisle and crew rest is extremely tight and only separated by an extremely thin curtain. On my last flight all of the cabin crew rest periods were disrupted by passengers banging into crew whilst taking rest. We were left fatigued and exhausted and this potentially can have an impact on safe operation by cabin crew.

Company CommentFlights that operate on routes without crew rest bunks facilities, or class 1 do not require an extension to the crew members’ FDP. The availability of crew seats at cabin doors (most are with curtains) are for cabin crew to take a refreshment break and time away from the cabin. The reporter is encouraged to familiarise themselves with the operations manual which details the rest requirements. The reporter is encouraged to report their safety concerns to us using the safety reporting method.

CAA CommentThis is not crew rest for FDP extension, this is a crew break. There is no requirement for crew rest areas unless the operator is extending FDP.

CHIRP Comment

Just because a flight is long and there is the time available for a ‘rest/break’ (in addition to a meal opportunity) this doesn’t mean that ‘inflight rest’ is required to operate the duty.

If the flight duty period (FDP) does not need to be extended then inflight rest is not required. However, in accordance with UK Retained Regulation ORO.FTL.240 Nutrition, a meal opportunity is required (although the provision of food is not).

If the maximum FDP does need to be extended, then ‘inflight rest’ is required.

An aircraft’s rest facilities can restrict what routes an aircraft operates due to the length of the FDP. Not all operators have all the below facilities available onboard.

‘Class 1 rest facility’ means a bunk or other surface that allows for a flat or near flat sleeping position. It reclines to at least 80° back angle to the vertical and is located separately from both the flight crew compartment and the passenger cabin in an area that allows the crew member to control light, and provides isolation from noise and disturbance;

‘Class 2 rest facility’ means a seat in an aircraft cabin that reclines at least 45° back angle to the vertical, has at least a pitch of 55 inches (137.5 cm), a seat width of at least 20 inches (50 cm) and provides leg and foot support. It is separated from passengers by at least a curtain to provide darkness and some sound mitigation, and is reasonably free from disturbance by passengers or crew members;

‘Class 3 rest facility’ means a seat in an aircraft cabin or flight crew compartment that reclines at least 40° from the vertical, provides leg and foot support and is separated from passengers by at least a curtain to provide darkness and some sound mitigation, and is not adjacent to any seat occupied by passengers.

Please remember that whether at home base or down route, it is an individual’s responsibility to manage their rest accordingly and to ensure that they are ‘fit’ to operate the duty, cabin crew should not be operating when they are unfit to do so. This report states that the crew were fatigued and exhausted, please ensure if you are suffering from the effects of tiredness and/or fatigue, that you report this to your operator.

-

CC6250

–

Passenger BagsPassenger BagsInitial Report

Onboard SCCMs consistently tell me to stow bags that are heavy – I have told the SCCMs I am not lifting the bags and that they should be offloaded if the pax can’t lift them. However, when a pax boards as a PRM the SCCMs typically tell me it’s not a choice as the pax is disabled. I have sought legal advice regarding our manuals and the legislation followed, stowing bags should be done by the airport managing body/its contracted staff.

Recently I pushed a very heavy bag and I felt a shooting pain in my neck, I winced as I pushed the bag. During my break I cried, I hid as to not be seen by the other crew. I was in pain and so hurt and disappointed with my colleagues. I am still experiencing pain in my head and neck. I cannot report sick for due to being on a temporary contract, I have a mortgage and family to think about and cannot risk not being employed further.

Company CommentA recent safety notice was issued providing crew a refresher on manual handling techniques, including the loading of bags into the overhead lockers. The techniques, if followed correctly, ensure that injuries are avoided when carrying out manual handling tasks. The safety notice’s accompanying video reaffirms the advice to ask for assistance from ground personnel and/or other crew members if a bag is too heavy. It should be reported internally and will be followed up on if a crew member experiences pressure from their SCCM. If the pertinent information is received, further action can also be taken with the Airport teams.

CAA CommentWhilst an operator is required to ensure that only those bags that can be adequately and securely stowed are taken into the aircraft cabin, such baggage is not usually individually weighed. Lifting of passenger baggage by cabin crew is a matter of health and safety and if a crew member considers a bag is too heavy for then to lift without potential for injury, they should not do so.

Such events should be reported through the company reporting system in order to enable the identification of trends relating to oversize or over-weight passenger baggage.

CHIRP Comment

All cabin crew should receive manual handling training. Good practice prior to assisting lifting a bag is to test the load of the bag first; crew must not lift bags that are beyond their lifting capabilities and should ask for assistance if it is required. For PRMs the special assistance staff should be available to assist with putting the passengers’ bags into the overhead lockers.

CAP757 states: ‘As far as possible, cabin crew should provide minimal assistance with passenger carry-on baggage and encourage passengers to stow their own baggage. Where possible, cabin crew should avoid lifting carry-on baggage into overhead lockers but, if no other solution can be found, the crew member should assess the baggage and, if necessary, request assistance before lifting it’.

Any bags that are beyond your lifting capabilities and/or your operator’s weight restrictions should be off loaded and put into the aircraft hold. If you are offloading passenger bags, then please ensure that you ask the customer if they have everything they need for the flight prior to taking the bag; including consideration for dangerous good restrictions, and passport and medication are must haves.

The safety implications of operating as crew when unfit to do so are clear. Safety may be being compromised by crews feeling pressured to operate when they are unfit to do so, whether it is perceived pressure from your operator or personal pressures. Although the reporter’s injuries occurred after they had commenced their duty, an assessment still needs to be made as to whether you are fit to continue to operate because flying when you are unfit may lead to the exacerbation of your symptoms and/or injury.

-

CC6321

–

ULEZ support solution and FTLULEZ support solution and FTLInitial Report

The Mayor of London is bringing ULEZ into enforcement in August 2023, the LHR long stay car park is within the charging zone.

HAL have put together a guide to ‘support employees’ however I have concerns regarding one suggested park and Ride and FTL for crew and pilots. This makes a commute that is 90 mins now 140 mins.

I know that this decision is not the companies, but I would like to know if this park and ride impacts at all on our FTL? Also, the facilities/frequencies aren’t sufficient for very early report times/late arrival times.

Park and ride Timetable, in order to make a 0600 report with staff search landside you’d have to catch the 04:18 bus. I don’t think this is viable option for crew from HAL or the company as we are stipulated by commute times unlike our ground based colleagues. The suggested new park and ride location outside the ULEZ would extend the commute by 60mins.

Company CommentXXX don’t tell people specifically how to commute. Cabin crew sign in to confirm their commute is within the guidelines set out and if this has not been met it is their responsibility to inform a manager.

As part of ULEZ expansion, instigated by the Mayor of London to reduce air pollution, the company has produced a fact sheet of the different options, in conjunction with London Heathrow, available to all staff who commute to the airport. Each will have different roles and responsibilities and should consider these when deciding how to commute. We appreciate that some of the options available will not be suitable for some of our employees.

CAA CommentThe CAA is currently conducting impact assessment of the recent enforcement on the effected aviation sectors.

CHIRP Comment

The Ultra Low Emission Zone (ULEZ) is planned to expand across all London boroughs from 29 August 2023. If you drive anywhere within the ULEZ, including the expanded area from 29 August 2023, and your vehicle does not meet the emissions standards, you will likely face a daily charge of £12.50. To check if your vehicle meets the emissions standards, visit tfl.gov.uk/check-your-vehicle.

This report was discussed in depth at the CHIRP Cabin Crew Advisory Board meeting in June and the reporter’s concerns were raised with the CAA. We have sympathy with those who have previously ensured that their personal circumstances meet their operators travel requirements and now find that they may face extended journey times or increased costs through no fault of their own. Unite the Union confirmed that they are campaigning at the highest levels for a postponement of the ULEZ program’s implementation until better infrastructure is in place, and we urge those who might be affected to check whether their vehicle is compliant with the ULEZ at the earliest opportunity. It is reported that less than 10% of vehicles will be affected but, if yours is affected, speak with your company/line management to discuss options – they may be able to assist. The ULEZ charge’s financial effects will extend beyond the crew to include all airport staff, which could have an impact on Heathrow’s staffing levels. Low emission zones, commonly known as “clear air zones”, are being implemented in many UK cities, and soon additional airports may also be impacted.

Regarding Flight Time Limitations (FTLs) as per any duty, if you think you could be suffering from the effects of fatigue please ensure you complete a fatigue report and assess whether you are fit to operate the planned duty period. There is a responsibility on each cabin crew member to ensure that should they not be able to perform the duties expected of them, that they report this to their operator.

The MEL is created and approved by the UK CAA to comply with all required regulations. As such, when the FAP is inoperative, it is permissible by the regulator not to dim the lights for take-off and landing if an AAP is not fitted, or inoperative.

With regard to the EMER EVAC from the cabin this would only ever be used in line with our procedures:

“The only occasion when the cabin crew will initiate an evacuation is when the situation is clearly catastrophic. In a clearly catastrophic situation the evacuation of passengers must be initiated without delay immediately the aircraft has finally come to rest.”

In such circumstances the evaluation would normally be initiated by the Flight Crew or by any other means e.g. loud hailer, as it is clearly a requirement to leave the aircraft.

There is no mandatory requirement for aircraft to have an evacuation alarm installed and the rectification interval for an unserviceable system will be determined by the Minimum Equipment List (MEL) for the aircraft in question. UK operators tend not to rely on an evacuation alarm as the only indication of evacuation, but also use evacuation commands, which may also be used in the event of system unserviceability.

Cabin lighting, such as passenger reading lights, are not mandatory airworthiness items and will therefore have a longer rectification interval.

The Operator creates the MEL based on, and no less restrictive than, the master minimum equipment list (MMEL). This MEL is then internally reviewed and approved before submission to the CAA for final approval.