FEEDBACK

So, just what are the main issues in GA?

You might be surprised by some of the problems and how to deal with them

As I write this editorial we’re just over halfway through the year so I thought it would be useful to give an idea of the main themes reported to CHIRP in the first 6 months.

The sundial chart at the end shows the associated top GA Key Issues on the inner circle and their relevant sub-issues on the outer wheel. Each report we receive can be ascribed more than one Key Issue or sub-issue and so care needs to be taken in interpreting the chart because one report might feature in a number of sectors but the aggregated results are informative in showing what the main themes have been so far this year.

In this respect, ‘Procedures’ represents the most common theme to date, representing 21% of the issues we’ve had reported. Most of the problems we’ve seen have been in the faulty application of, or did not follow, procedures. But a sizeable chunk also covers lack of understanding and poor knowledge so there’s definitely a case for reviewing some of those aspects of flying that you’re uncertain of or don’t encounter on a day-to-day basis so that you understand and are ready to apply the correct procedures whenever called on – time to review your aircraft’s pilot’s operating handbook and your home base airfield operations manual perhaps.

‘Defences’ refers to how well we are equipped to anticipate and deal with problems that arise. Some problems are difficult to anticipate because they may be insidious in their manifestation, but one of the things we can help ourselves with here is in conducting a thorough Threat and Error Management (TEM) process to assess what might go wrong and what risks might be present. Threats relate to the external things that might go wrong, whilst Errors relate to things that we might get wrong ourselves. TEM is the deliberate thought process that we should conduct before (and during) a flight so that we continually review what we’re about to do so that we can anticipate problems. There are of course endless things that one could list as potential problems but focusing on the existential ones is a good start: what would I do if my take-off performance doesn’t match expectations; what if the enroute weather isn’t as good as forecast; what would I do if the engine quits or runs rough; do I have a Plan B if my destination airfield is closed or weathered out; what would I do if I had a comms failure; have I properly studied the destination airfield topography and strip lengths etc?

‘Communications – External’ is all about making ourselves understood, and understanding what’s being said to us. I featured this in the recent GA FEEDBACK Ed 145 editorial so I won’t labour the point except to highlight the need to use the recognised phrases and pro-words on the radio rather than cool and trendy slang, and to speak clearly and deliberately so that everyone else has the chance to understand exactly what you’re saying. Safety Sense Leaflet 22 provides a good aide memoire about communications and radiotelephony in general that’s not too heavy going so it’s worth a read.

‘Situational Awareness’ and ‘Airmanship’ often go hand-in-hand so it’s not surprising that, together, they represent a largish chunk of the issues that we see. Improving Situational Awareness often comes down to taking advantage of all the information sources that are available to you so that you can synthesise the best understanding you can about what’s going on. Thorough pre-flight planning, electronic navigation aids, Electronic Conspicuity systems, being on a useful frequency, listening to and passing information to others, and making use of ATC when it’s available are all ways of building as comprehensive a picture as you can. Airmanship is then, to a large part, often about how you use that picture to best advantage through the 3 ‘C’s of Caution, Consideration and Courtesy for others, and then making appropriate decisions to choose the best course of action.

Finally, ‘Individual Error’ covers a wide range of actions that may or may not be circumstantial and are mostly unintentional. Never forget that you’re human, and humans make mistakes and errors, so it’s back to that TEM thing again where you need to be honest in your personal analysis of your weaknesses and potential lack of experience or currency! The exception being ‘complacency’, which is pretty much an own-goal in performance terms. ‘Don’t assume, check’, and ‘Assume makes an ass out of u and me’ are well worn phrases but their meaning is clear. Every day is a learning day in aviation so don’t accept poor planning, poor behaviours, ‘that doesn’t look right but I’ll carry on’ or ‘it’ll be OK this once’ because that’ll be the day something comes and bites you on the bum.

The bottom-line? CHIRP provides a vital safety net as another route to promote change when the normal channels of reporting aren’t delivering results, you don’t feel able to report through formal Occurrence Reporting systems, and for collecting reports with safety concerns that did not meet the threshold for normal reporting and would otherwise have gone unwritten. We rely on you to report Human Factors aviation-related safety concerns to us so that we can both help in their resolution and highlight relevant issues to others. Reporting is easy by using either our website portal or our App (scan the appropriate QR code shown or search for ‘CHIRP Aviation’ – avoiding the birdsong apps that come up!). In our reporting portal you’ll be presented with a series of fields to complete, of which you fill in as much as you feel is relevant – not every field is mandatory, but the more information you can give us the better. Although you’ll need to enter your email address to get access to the portal, none of your details are shared outside CHIRP, and we have our own independent secure database and IT systems to ensure confidentiality.

![]()

GA Key Issues & sub-issues reported to CHIRP Jan-Jun 2023

Fuel Filters and Filling Points

A couple of concerns about fuel systems came to our attention recently and so I thought that there would be value in raising awareness and possible further discussion about Fuel Filters and Filling Points.

CHIRP recently received a report relating an incident with an aircraft that had been in storage during COVID. Fuel had been left in the fuel tanks for quite some time. The pilot decided to drain the main tank and add fresh fuel. This flow of fresh fuel, unbeknown to the pilot, drew all the debris in the tank to the Gascolator.[1] The Pilot typically drained some fuel from the Gascolator before flight and, seeing nothing of concern, flew the aircraft only to suffer a misfiring engine and a precautionary landing.

On inspection, the Gascolator was completely contaminated with accumulated foreign object debris (FOD). Including particles far too large to exit through the Curtis drain valve, which would have given an indication of a fuel contamination issue. The first area of concern is that metal Gascolator bowls do not allow easy visual inspection of water and FOD levels. A glass Gascolator bowl would be ideal for a visual inspection but can also be a really good unintentional source of fuel in an accident. Unfortunately, clear plastic bowls could be prone to discolouration and/or embrittlement from contact with the fuel.

[1] A gascolator, also known as a main line strainer, sediment bowl or fuel strainer, acts primarily as a fuel drain for water and small particles of sediment and is usually found at the lowest point of an aircraft’s fuel system. The gascolator is located below the level of the aircraft’s carburettor and fuel tanks and on light aircraft is commonly located on the front of the firewall, as low as possible. There are two types of gascolators: those tapped for a primer port and those without. If equipped with a primer port the aircraft fuel primer will take its fuel supply from the gascolator, used for engine starting.

Secondly, the size of the Curtis drain valve in this case meant that the larger FOD items were retained and so nothing untoward was noticed. As an aside, FOD build up can sometimes contaminate drain valve seals with particles which can cause the valve to leak. So, not only should you be checking the drained contents for contaminants and water, but also check that there is no drip/flow after closing the valve because this can be another indicator that there’s FOD in the fuel. Whilst on the topic of drain valves, note that some are able to be locked in the drain position (i.e. the valve can be twisted to hold open on a detent as shown in the picture). AAIB Accident report G-BZDA described an incident where power was lost due to fuel starvation when one of these was left in the locked open position. This resulted in an associated CAA Special Notice (SN-2021-005 now rescinded) that highlighted the risks associated with lockable gascolator drains and was later amended to include a recommendation that aircraft be checked for appropriate placarding at the next scheduled maintenance event.

Finally, although the pilot was being rightly cautious about flying with fuel that had been in the tanks for some time, it is not sufficient simply to drain and refill fuel tanks following a prolonged period on the ground. Contrary to CAP 1919 ‘Safety advice and tips for pilots returning to GA flying post COVID-19’, which simply recommends draining and replacing fuel, after significant periods on the ground the whole fuel system needs to be fully flushed and cleaned because the fuel may have degraded to the extent that particles may be present in any part of the system; the tanks, fuel lines, gascolator, fuel injectors/carburettors etc all need to be checked and cleaned to ensure they are not contaminated or blocked with debris.

Moving on to Fuel Filling ports, our US NASA equivalent, ASRS (Aviation Safety Reporting System), recently issued an Alert Bulletin in reference to Cessna 172 Fuel Tank Filler Tube Integrity (ASRS Report No 19944807, see text below). CHIRP contacted Textron and it would seem this has been a concern including other types for a considerable period. The likely cause is that those refuelling the aircraft are placing a strain on the filler neck with the refuelling nozzle. This, like the Gascolator issue above, may apply to a range of aircraft types from various OEMs. Vigilance is required to ensure that the individual carrying out refuelling takes the strength of the filler neck into consideration, and some recommend that the person conducting the refuelling places the fuel hose over their shoulder so that the weight of the hose is not bearing directly onto the filler neck itself; this is especially relevant to high-wing aircraft where the extra length of hose from the ground can significantly increase its weight and therefore the strain on the filler neck. This may further require a formal competence assessment of staff or club members who carry out frequent refuelling duties.

ASRS Report No 1994807 text:

… I departed ZZZ in a C172 with a student working on his instructor rating. Shortly after take-off we smelled raw fuel fumes and returned for a landing. The scent of the fumes got stronger in our descent. The student asked me to land. On the ground he told me he got a migraine headache from the fumes. It appeared he was incapacitated from the fumes. If he was by himself this could have been deadly.

The plane was withdrawn from service and the fuel tank sent to a welding shop. Apparently the filler tube developed a crack where it is welded to the gas tank. We were lucky that there was no fire or explosion, as in Aircraft Y. This was the second time this year that this fuel tank leaked. Last [eight or nine months ago] I refused to fly the plane after smelling fumes on another training/demonstration flight. The plane continued to be operated by other instructors and students, despite my emailed warnings to them, until it was pulled from service for its 100‐hour inspection. The fuel tank was apparently sent to a welding shop for repair.

I spoke with another Aircraft Inspector who works for a different school and was told that this was a common problem in their Cessna aircraft. This Inspector believes the problem is caused by the fuellers letting the fuel nozzle apply too much force on the filler neck. Our Inspector/Director of Maintenance thinks this is caused by the fuel tank walls or top flexing, and causing stress cracks where the nozzle is welded. Person A at Company confirmed that a lot of Cessna fuel tanks have cracks where the filler neck joins the top of the tank. They seem to think it is from the fuellers letting the nozzles put too much pressure on the filler necks. However, they said the top of the tanks also develop cracks.

The Cessna leaking fuel tanks appear to be a systemic problem …[Regulator] should warn pilots to have mandatory fuel tank inspections [and] ground the aircraft anytime there is the smell of fuel in the cockpit or fuel stains behind the filler caps or under the wing above the door. Some operators have taken the step of not filling the fuel tanks to the top. However, in a descent, there will be fuel behind and consequently above the filler neck to create a pressure head to drive fuel through the crack in the neck weld. Partially filling a tank with a known leak should be considered operating an aircraft in a reckless manner…

Phil Young CHIRP Engineering Programme Manager

Comment No 1: Gone dotty? Dear CHIRP, the last issue [GA FEEDBACK Edition 96] was a thought provoking and enjoyable read as always, for which many thanks. Just one minor point from the “Speechless?” comment [regarding making contact using the speechless code when experiencing a microphone failure]. There is no letter corresponding to four ‘dashes’ (long bursts) in morse code. Four ‘dots’ (short bursts) corresponds to the letter ‘H’. A relatively minor point I suppose, but morse code identifiers are still used by NDBs and VORs so we should try to be accurate.

CHIRP Response: Dash it all, it’s a fair cop, I got carried away with meeting publishing deadlines for the last edition and confused my dots and dashes! The comment should have read:

For those who may not be familiar with the speechless code, it was conceived as a military procedure used to enable a set of yes/no questions to be asked by ATC when an aircraft had a microphone/voice-transmit problem. The procedure can be initiated by either the pilot or the controller depending on who recognises there’s a problem. If it’s the pilot who realises they have no voice transmission then you initiate the procedure by pressing 4 times on the transmit button to send out 4 bursts of carrier-wave (4 dashes dots being morse ‘H’ for ‘Home’)

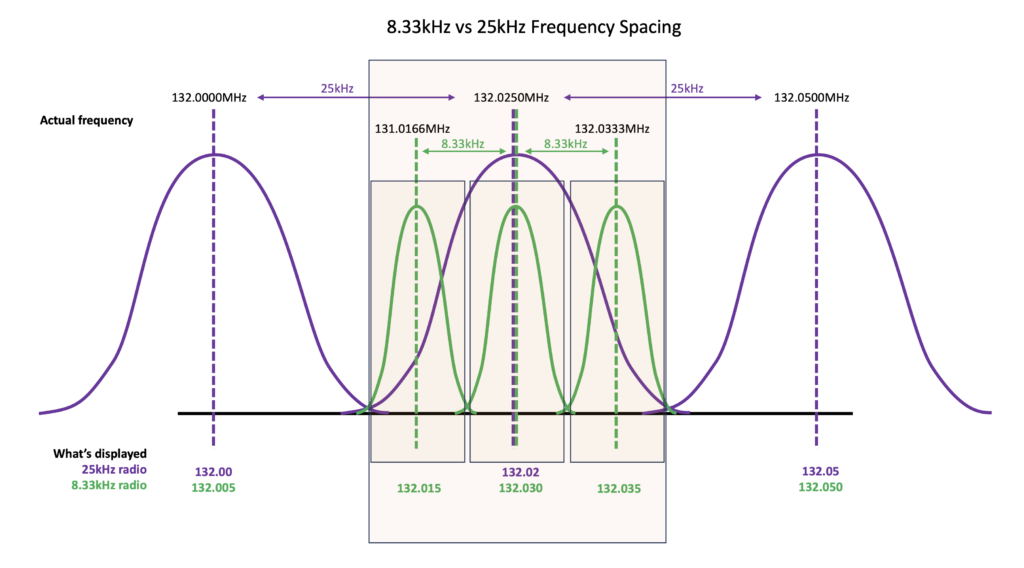

Comment No 2: 8.33kHz radios. I thought the attempt to clarify 8.33kHz spacing was very poor. The “house” analogy was confusing and inadequate. Remember “One picture is worth a thousand words”. It would have been much clearer using a diagram showing how the peak signal strengths fall off when measured at frequencies departing from the original – a Bell curve. Start by showing two adjacent 25kHz channels as originally operated, then insert more 8.33 channel bell curves showing how much narrower the curves are, with reduced chance of receiving an adjacent channel. CAP1573-833-Ground station offers some information in tabular form, unfortunately using 118.00 as an example. This is in the frequency range allocated to navigation channels, not voice comms.

Comment No 3: QFE vs QNH. Further to the Feb 23 GA edition [GA FEEDBACK Ed 95], I periodically fly between White Waltham and North Weald, both of which have ATZs which are coincident and below the CTA. One insists on the use of QFE to avoid infringement, the other QNH. Which is correct? QNH wins for me (and the rest of the western world).

CHIRP Response: The debate about QNH vs QFE is a perennial topic that has protagonists on both sides and a long list of comments in support of both views; some are pro-QFE, some are pro-QNH. There are no doubt sound reasons for some airfields going either way, and the debate about QFE vs QNH in the visual circuit and immediate environs is well-rehearsed by both camps. I don’t think anyone can disagree about the use of QNH for transits overall, but some hold to the value of QFE in the visual circuit for simplicity of operations. At the risk of sloping shoulders, perhaps the time has come to have a serious national review and debate, if only for the benefit of consistency and commonality.

I’m a GA pilot who utilises my small-group PA28 Warrior II for recreational purposes. At the point of writing, I have logged 296 flying hours of which the majority are on type, I’ve expanded my knowledge base by undertaking my IR(r), I fly often to stay current, and I have capabilities that have a limit in GA terms. I was undertaking a very routine and non-eventful flight from my home airfield in Norfolk to an airfield in East Riding. After a few hours at our destination, it was time to return home. As I departed with my passenger, I thought the journey back would be as uneventful as our arrival, how wrong could I be.

On departing the East Riding airfield area I changed frequency to Humberside Radar. Climbing through 2500ft, my passenger asked me what had appeared on the lower part of the front screen on his side of the aircraft. At first, I could not see what he was referring to, then a further smear appeared. I initially thought that it was water, however within seconds the liquid began to spread in finger formation up the front screen and I could quite clearly see that it was yellow and quite thick! Oil! On turning my vision back to my side of the screen, I noticed that the liquid had now also appeared on both sides and it was quite quickly covering the screen and blocking my visibility entirely. This is the first picture my passenger took.

Quite quickly our position worsened when the oil started to spread in a similar fashion along not only the front screen but also the side windows of the aircraft. Very quickly the passenger window became completely blocked and my side window provided only a partial lower view. I immediately knew this was not going to play out well. I was at this point a little unsure of what that outcome would be or how bad the situation would become, but various thoughts quickly ran through my mind.

Within a minute of the incident commencing the only visual aspect I was left with was a small section on the lower left of the front screen allowing me to see downwards but not forwards. Having the small direct view window (which is very difficult to actually use to fly with), I was able to utilise this to crab the aircraft a few times to try and provide some form of directional guidance and a visual mind picture of what was ahead (a town and a big river!). On checking the Temperatures, Pressures, and all other gauges I was somewhat surprised and relieved to see that the aircraft was performing correctly and not indicating any system fault (yet). I was not sure how long this position would last, and I knew I had to get on the ground and very quick. I immediately spoke further to Humberside Radar and requested a divert to them. After some standard communication, we established that a straight in approach onto runway 20 with a tailwind was a better option than flying an approach to the in-use 02 runway. I am very grateful for my instrument training, having practiced numerous and various approaches into Norwich, Cambridge and Southend I have always taken the view that an SRA approach, (irrelevant of my skill at flying a plate procedure) would always be my chosen method should the need arise. That need was right now.

The CFI at my flying school (an excellent instructor) had made me practice SRA approaches – it was during these practice approaches that we discussed in detail how an SRA approach is much easier on the workload than a full procedural approach if in trouble. I did not have the approach plates for Humberside to hand, and whilst I am aware how to import them onto Sky Demon whilst flying, my workload was somewhat stretched trying to ensure my passenger was ok (he was exemplary and very helpful) and I was trying to run through various scenarios that could play out and my planned actions should the engine suddenly stop or should I see flames.

As we commenced the SRA procedure, I instigated the wings-level auto pilot (something I practiced a lot after obtaining my IR(r)) and began to concentrate on the instruments and gauges in front of me. Having plugged in a direct route to Humberside, I commenced the extended SRA from Hornsea and utilised the instruments and sky demon to point towards the runway 20 heading. The direct route from Hornsea to Humberside is 21nm and according to Sky Demon 13 minutes, that 13 minutes felt a lot longer!

Whilst concentrating on the ‘Aviate, Navigate, Communicate’ process dealing with issues right there and then, it suddenly occurred to me that in all my instrument training I had never actually landed the aircraft as part of the procedure (there was no requirement to) and all of my approaches and missed approaches had been flown on a QNH setting terminated at either the decision height or via a missed approach go-around procedure, either way they had all been based on the ability to see the runway! This position was something quite different.

A brief discussion with the controller confirmed that I would not actually be able to make a decision as I could not see ahead or out of the side window, hence at 600ft or 300ft there was only one way this was going to end, I was landing, and landing very much blind! I asked for the QFE and began focusing on how to land the aircraft, not only with a tailwind, but with the sun beaming into the cockpit and having no forward or side vision. I quickly established that to crab or fly any other unusual approach would potentially put further stress on my mental state, and I did not want to keep adding additional power to stabilise the aircraft should a crab with a tailwind put me off track. I was also conscious that I was maintaining a steady descent which was confirmed as part of the SRA approach with the controller. Little power bursts were also creating further oil spurts, oil spurts meant less oil which could result in less pressure, less pressure meant a rise in temperature, the combination of those together made for an even worse scenario than I was trying to control.

As the descent continued I was able to crab a couple of times had managed to glimpse the runway and the large expanse of grass to its left. I knew that if I could get to the threshold, I could drop a third stage of flap quickly and I would land before the end.

I fully appreciate the concerns the controller would have had, a GA aircraft with no visual front or side aspect being talked through a procedure into an active airport with a 21-mile approach, whilst not knowing if the pilot was instrument rated or the level of experience or currency of the pilot. I believe our mutual understanding of the position became clear when I advised that I would not be able to follow through with a decision height confirmation as I had no ability to see to make that decision.

At the point I realised that my glide would take me to the airfield, I also decided that a perfect landing on the centre line with no forward vision was not for me. For a vast amount of the descent I had been visual with a large piece of grass that ran parallel to the runway, I kept telling myself, I’m not a commercial pilot, I’m not being judged on the landing and from all of my training and my GA experience a bad and heavy landing on grass is always somewhat more appealing than the same on tarmac. I didn’t tell the controller of my intention to aim for the grass, I think I may have been afraid of him saying no! (I’m sure he wouldn’t) but that last 30 seconds was somewhat testing. Any landing that you walk away from is a good landing (as one of my first instructors kept saying!)

Some 30 minutes after taking off from East Riding, and having flown for the very first time as an IR not IR(r) pilot and having landed successfully on the grass, I positioned the aircraft onto the centreline of Runway 20, blue lights flashing around me, with a fireman looking at me as if I was mad having landed on the longer grass rather than the beautiful runway we now all sat upon. I could only congratulate my passenger for his belief in me. There we sat, our emergency over! As I was taught, an emergency landing should have a real expectation of preservation of life, limited injury being caused and, if possible, an intact aircraft. I chose the grass as a safety and comfort blanket. On this particular day that blanket worked.

Would I change any decisions I made? Well I’m here to answer that, so the answer is clearly a ‘No’. Would I do the same again? Absolutely. Since the incident, I have run the scenario time and time again in my head and sat in the aircraft. I am in no doubt the grass would have won over an attempted blind perfect landing on the centre line of Humberside Airport every time. Human Factors played a huge part in this incident, training and currency being the most important factor, along with trust in the excellent controller.

The engineers report confirmed that the oil leak came from the end of the crankshaft ID; there had been approximately 2lts of oil dumped onto the screen and subsequently the rest of the aircraft. On leaving the aircraft it was quite surreal to see the amount of oil that had made its way from the front screen to the rudder and every part (including the wings in between). A close up of the screen from the outside shows the battle that had just been won, it’s a little like trying to drive a car with bathroom obscured glass fitted!

The CFI from my homebase contacted me the day after the incident and we met up that day to talk through the event, we discussed my decisions and the reasoning for them, not to criticise but to learn and expand knowledge. Human Factors played a huge part in my planning (Humberside was my fuel and emergency divert for the route that I had worked through the evening before my flight). I didn’t realise how helpful it would be getting into a small 2-seater Cessna the day after with the CFI. There are many things I have personally learnt about myself from this experience, and I am not naïve enough to think that this incident is my last run with trouble. I have some strong views on instrument training, not IR(r) but basic PPL extension instrument training, but that’s for another day. For me, I’ve signed back up to revalidate my IR(r) and I shall ensure I keep very current with emergency procedures, all so I’m ready for the next time things go a little wrong once again!

Steve Forward

Former Director Aviation

-

GA1319

–

Infringements – or what almost happenedInfringements – or what almost happenedInitial Report

The initial report and protracted subsequent responses and communications are published in précis due to lack of space. In summary, this report came to CHIRP in May 2022 and related to an airspace change involving the introduction of Class C airspace and changes to the vertical extent for the Daventry CTA and Clacton CTA. The reporter was from a flying school, and they had not been aware of the consultation for, or implementation of, the airspace changes (November 2021 and February 2022 respectively) due to the fact that they had not been flying over the period because of COVID/weather restrictions. By the time they had returned to flying in mid-March 2022, the associated NOTAM had been replaced by an AIC (AIC Y 006/2022) and the VFR chart had yet to be updated (the new Edition 48 Southern England and Wales 1/2mil map became available on 27th March).

The long and the short of it was that they got airborne unaware of the change, and it was only by good fortune that they did not infringe the new airspace. Setting aside the issue of personal and organisational responsibilities to check AICs etc when they returned to flying, with regard to airspace changes the reporter opines that the introduction of the ‘Luton Airspace’ change wasn’t very well communicated, and they suggest that any such changes should remain as active NOTAMs until after the publication of the associated revised VFR chart. More specifically, the reporter commented that, in their opinion:

It is second nature to start the day looking through the Met Office website and reading through the NOTAMS on the AIS website. The UK AIP is far too large a document to be comprehensively read before each flight; that’s why we have NOTAMS, or should have.When training in our local area, that’s most of our flights, we look at NOTAMs by selecting the Point PIB, typically with a radius of 25nm from our home base.

I have not been a part of the consultation on the new airspace and I would say that I look to my representative organisations, the British Microlight Aircraft Association (BMAA), the Aircraft Owners and Pilots Association (AOPA), and the Light Aircraft Association (LAA) to comment on behalf of their members. Flying schools have little in the way of resources to comment on the numerous and lengthy consultation documents produced.

Whilst on the topic of NATS promulgation of airspace information, NATS Briefing Sheets exist to cover events where they will occur at notice too short to be included in the AIRAC cycle. But the existence of Briefing Sheets is unknown to many GA pilots. Should a pilot be searching for Briefing Sheets on the NATS website they are not to be found under the expected heading of Briefings or the next logical heading of NOTAMS but under Publications.

Overall, the reporter said that the issue was one of communications and that their recommendations were:

-

- To publish a document, for example, a yellow AIC on a website and not tell us about it when we need to know, that’s on the day we do our flight planning, is not useful. The imposition of a new block of controlled airspace should be notified as a NOTAM from the date of inception until it has appeared in the new editions of the relevant maps for such time as is required for the GA community to know of its existence. If NATS are concerned about a proliferation of NOTAMs, I recommend they discontinue publishing those referring to Ethiopia, Ukraine etc; they appear for months on end and are of no relevance to a circle of 25nm radius around an airfield.

- The existence of Briefing Sheets and how to access them should be publicised throughout the GA community.

- The CAA should review their oversight of NATS communication of NOTAM information to GA.

- The CAA should consider engaging an advertising agency to define the methods and media and style to be used in communication; they are experts in putting a complicated concept into simple form appropriate to the target audiences.

The reporter also forwarded some of their comments to the BMAA, one of their representative associations.

CHIRP Comment

Although we have sympathy regarding the perennial problem of airspace changes sometimes not being reflected on VFR charts for some time after they are invoked, pilots and organisations have an individual responsibility to ensure that they use charts that are up-to-date with the latest chart amendment standard (as shown on the NATS AIP website in the ‘Charts’ section) before every flight. It is, however, acknowledged that there are often numerous amendments that are not always immediately obvious as to which part of the chart they apply.

With regard to communication of such changes, we agree that the current system appears to rely heavily on aviators ‘pulling’ information from websites rather than NATS/CAA persistently ‘pushing’ the fact that a change has been made. The CAA SkyWise notification system is a good start for initially highlighting a change, but it relies on people being subscribed and, whilst most flying clubs and organisations may well be, individual pilots may not. With respect to publishing NOTAMs that contain airspace change information until the next edition of the relevant VFR chart is published, CHIRP’s view is that this is probably not ideal given that NOTAMs can only be in place for 3 months and it could in extremis be up to a year before the associated VFR chart is updated – we don’t want to increase the number of NOTAMs in what is already a fairly user-unfriendly system.

But we do think that more should be done to provide an easily accessible resource that shows all airspace changes that have yet to be published on the VFR chart, along with NOTAM information. Currently, the Chart Amendments section on the NATS website provides a list of changes but a graphical interface that could be zoomed and localised to a particular area to show chart and other airspace information changes would be of great benefit to the aviation community as a briefing resource, as would a better user-guide on how to access and filter NOTAMs. CHIRP engaged with NATS on information promulgation and received some detailed responses that we don’t have space to reproduce here but which can be accessed on our website Hot Topics.

Key Issues relating to this report

Dirty Dozen Human Factors

The following ‘Dirty Dozen’ Human Factors elements were a key part of the CHIRP discussions about this report and are intended to provide food for thought when considering aspects that might be pertinent in similar circumstances.

Resources – poor NATS AIS website user interface

Awareness – the reporter was not aware of the airspace change

Knowledge – the information was available but not obtained

Communication – the NATS AIS system relies on users ‘pulling’ information by knowing where to look on the website; more pro-active and persistent publicising of changes using a graphical interface would help

Complacency – the reporter did not review the AICs before returning to flying after a long layoff

This data type is not supported! Please contact the author for help. -

-

GA1341

–

NOTAM Information Missing or IncompleteNOTAM Information Missing or IncompleteInitial Report

The NOTAM Info web site at [website] has had a serious fault since late December 2022. Attempts to report this to the site owner have gone unanswered. The site shows no warning about the fault and appears to work correctly. Pilots who habitually use the site may rely on it as their sole or main source of NOTAM information and may consequently be unaware of important NOTAMs resulting in entry to temporarily restricted airspace or even a collision. The nature of the error is that the software is designed to retrieve all the NOTAMs for the next 7 days. However, from 29th December 2022 onwards, NOTAMs are only retrieved for the next hour. It wasn’t until mid-January that I first realised that I wasn’t seeing all the NOTAMs relevant to my planned flights. I reported the problem using the CONTACT form on the web site. I have had no response so far and the error persists. I have alerted other pilots to the problem and now use the AIS web site to retrieve NOTAMs. [Note, the website has subsequently been corrected which is why we don’t mention its name]. I admit to taking the short cut of using a non-approved source to get my pre-flight NOTAM briefing. I mitigated that by calling the free AIS Information Line number 08085 354802 which is what made me realise that I wasn’t seeing all the relevant NOTAMs.

CHIRP Comment

Although this report refers to a specific website, the issue is much wider in that it highlights the risks of using uncertified 3rd-party NOTAM websites and electronic planning aids that might have errors or missing information. The definitive source of NOTAM information is the NATS AIS website but, in many respects, it’s not user-friendly and so this is why people use 3rd-party providers. CHIRP has engaged with NATS about this in the past, and improvements have been made in many aspects, but we are pressing them and the CAA to provide a more graphical, chart-based NOTAM and airspace change interface to make them much more user-friendly.

The bottom-line is that although some 3rd-party NOTAM providers may well provide a more functional user interface, they are not the definitive source of NOTAM information and so should be used with extreme care.

Key Issues relating to this report

Dirty Dozen Human Factors

The following ‘Dirty Dozen’ Human Factors elements were a key part of the CHIRP discussions about this report and are intended to provide food for thought when considering aspects that might be pertinent in similar circumstances.

Resources – poor user interface for NATS NOTAM retrieval causing people to use 3rd-party websites

Knowledge – potential for errors or omissions in 3rd-party NOTAM websites

Complacency – assumption that 3rd-party NOTAM websites provide definitive NOTAM information

This data type is not supported! Please contact the author for help. -

GA1343

–

Pitot cover left onPitot cover left onInitial Report

A fellow group member and I had gone out for a lunch away on a fine flying day, with light winds and fluffy scattered Cu. He took the outbound leg, and I brought us back to base. We parked on the Visitors Line because I had arranged with an instructor that I’d go back out with him in a couple of hours’ time to do my biennial. There was plenty of fuel aboard, and I didn’t bother with any “putting to bed” things like pitot cover, exhaust bungs, canopy cover, etc.

Time came for the biennial flight and, after a briefing in the club house, we walked out to the aircraft, parked with its tail to us on the Visitors Line, climbed inside, and went through normal start-up procedures, taxi, checks, and take-off. All was normal until lift-off, when glancing at the ASI, I saw implausibly low figures. First disbelief, then confusion, then acceptance that I had no air speed indication. I guessed that the pitot cover might still be on, although I hadn’t put it on when leaving the aircraft earlier.

Next, fly the aeroplane. Pitch and power and control pressure and sound, orchestrated to provide me reasonably good guidance on air speed. The instructor, to my right, gave me readouts on ground speed, as displayed on SkyDemon. We made one circuit and landed without drama. Shut down at the hold, and the instructor leapt out, went around to the port wing, and brought the pitot cover back to me. We took off again, with a good ASI, and had a very pleasant flight.

Afterwards I surmised, and later confirmed, that after our earlier lunch-away flight, my friend had installed the pitot cover while I was doing post-flight paperwork and I hadn’t noticed. So when I walked out with the instructor for the later flight, I assumed the aeroplane was ready to fly. Long ago, a wizened old instructor informed me that “ASSUME” has no place in aviation, as it makes an ASS out of U and ME. This incident taught me that I should remember that maxim, and never skip a walk around after leaving and later returning to an aeroplane, assuming it will be as I left it.

CHIRP Comment

As the reporter infers, the pre-flight walk-round is an essential activity that must not be skipped; anything could have happened to the aircraft after it has been parked, ranging from a helpful person putting covers on as in this case to someone driving or taxying into it and causing damage. Given that the subsequent flight was a biennial check, one of the things that an instructor could usefully do is to accompany pilots when conducting their walk-rounds so that they can not only confirm that the right things are being looked at but also offer thoughts on other aspects of ground operations and aircraft readiness to fly.

As an aside, although the reporter coped well with the situation once airborne, don’t forget the value of checking that the airspeed is registering early in the take-off run. Had the reporter done so then they would likely have noticed that the ASI was not indicating and could have aborted the take-off prior to getting airborne. Although it’s not a formal rule, many use the rule-of-thumb that the aircraft must achieve 2/3 of the take-off speed within 1/3 of the calculated take-off distance. It’s always a good idea to have a marker in your mind at the side of the runway if possible for this distance where you will check the airspeed has increased as expected. In doing so, you’ll not only detect things like pitot covers being left on, but will also detect things like an engine that isn’t operating correctly or the aircraft isn’t at the all-up weight you think it is. If you don’t achieve the 2/3, 1/3 rule then abort the take-off and investigate.

Key Issues relating to this report

Dirty Dozen Human Factors

The following ‘Dirty Dozen’ Human Factors elements were a key part of the CHIRP discussions about this report and are intended to provide food for thought when considering aspects that might be pertinent in similar circumstances.

Awareness – the pitot cover was there to be seen but wasn’t checked

Teamwork – the instructor should have confirmed that walk-round checks had been completed

Complacency – assumption that the aircraft was in the same state as it was left; not checking airspeed early in take-off run

Deviation – walk-round checks not carried out

This data type is not supported! Please contact the author for help. -

GA1344

–

Pleasure Flights Within the CircuitPleasure Flights Within the CircuitInitial Report

There was an [Aircraft] doing figure-of-8 patterns within the circuit over the runway at 500ft. An email had gone out to private owners declaring that the aircraft would be operating, but not that it would be in the overhead. I’m unaware if anything had been added to the PPR page on the website. A couple of other resident owners mentioned that they were somewhat surprised to see an aircraft flying in the opposite direction 300ft below whilst downwind in the circuit. Without a NOTAM in place, or someone in the Tower on radio, it seemed an unusual activity that represented ‘in my humble opinion’ an unacceptable risk should a visiting aircraft need to have ‘gone round’ and climbed into the pattern taken up by the [Aircraft]. The [Aircraft] was operating with a good radio and could be heard but, having said that, one shouldn’t assume that everyone’s radio installation is to the same standard, and there is always the opportunity for two stations to be transmitting at the same time and the message doesn’t get heard.

Aerodrome Operator CommentIn addition to our website, our entry in the AIP, section AD 2.20, Local Aerodrome Regulations, provides information and a warning on possible [non-standard] activities over the airfield with aircraft possibly operating non-radio. Other publications also refer to the need to PPR via our online booking system and detail potential airfield activity. The following information was posted on the PPR webpage for those seeking to fly-in, and resident pilots were also advised.

Caution: … [Aircraft] will be carrying out multiple [non-standard] flights from the aerodrome. The [Aircraft] will be operating within the immediate vicinity of the airfield carrying out figures of 8, turns and orbits at 500ft AGL. All other traffic must use the standard circuit height of 800ft AGL for de-confliction and maintain a good look out.

For operational reasons, it is not possible to prohibit arrivals/departures to accommodate the activity because the exact flight times are subject to variation on the day. For the future, we acknowledge a need for additional notification and will NOTAM accordingly. Also, wherever possible we will provide an Air Traffic Service.

CHIRP Comment

The airfield accepted that more could have been done to highlight the pleasure-flight activity by NOTAM to both resident and non-resident pilots, and that they will do so in future. Whilst it is true that the airfield’s website PPR page warns that all aircraft wishing to use the airfield should be aware that they must stay well clear of any aircraft carrying out display practices at the airfield, and we note the airfield operator’s comment that, “For operational reasons, it is not possible to prohibit arrivals/departures to accommodate the activity because the exact flight times are subject to variation on the day”, CHIRP thinks that there is a case that, given their potential for conflict in the circuit, activities such as figure-of-8 pleasure flights over the airfield should be constrained to specified, promulgated time slots that other pilots can then plan to avoid rather than operating at ad hoc times.

Key Issues relating to this report

Dirty Dozen Human Factors

The following ‘Dirty Dozen’ Human Factors elements were a key part of the CHIRP discussions about this report and are intended to provide food for thought when considering aspects that might be pertinent in similar circumstances.

Resources – availability of Tower/ATS during an unusual activity.

Communication – a NOTAM highlighting the activity would have been preferable.

Complacency – regular unusual activities may lead to an assumption that other pilots will be aware of the associated risks; unusual activities such as pleasure flights should be constrained to specified, promulgated time slots.

This data type is not supported! Please contact the author for help. -

GA1345

–

PA28R Undercarriage WoesPA28R Undercarriage WoesInitial Report

I was a PPL scheduled on a flying school aircraft that I know well for a recreational flight to maintain currency. This was the first flight for the aircraft after coming out of maintenance. I was, fortunately, unaccompanied. The plan was for 3 visual circuits then a departure to the south for an IFR RNAV re-join.

Take off and turn to downwind was uneventful and I commenced downwind checks. On turning base leg I checked for 3 greens and was surprised to see nil. I turned final and requested a low pass from Tower. Tower informed that they could see undercarriage down but professionally reminded me that “down” and “locked” were not the same. Another aircraft confirmed this visually. I requested and was granted transit to the south to “sort myself out” and shifted frequency as instructed from Tower to Radar.

I retrieved the checklist “emergency gear down” and recalled from memory my retractable undercarriage conversion training. Accordingly, I checked the circuit breakers, deployed the emergency landing gear selector and yawed the aircraft from side to side. From the way the aircraft handled I actually had less confidence that the gear was down and locked using the emergency gear down control than when utilising the usual switch gear.

The aircraft felt as she always did so I moved the gear lever to the “down” position and watched the “gear transitioning” light go out and the 3x “gear safe lights” not go on. I even tapped them hopefully. I then felt that I had done what I should have done and it was what it was.

I called radar (who were providing a BASIC LARS) and informed them that I wished to declare an emergency. I was instructed to hold whilst conversations were held and then instructed to squawk 7700 and join via a left base. I performed a 2nd low pass across Tower (whose visual confirmation was as before), and re-joined the circuit that I had to myself by now, to land. The sight of the airport fire service at full deployment managed, if possible, to raise my focus further. Having said that I really believed that I had an indicator problem, not an undercarriage problem, she was flying like a PA28R with the wheels down.

So I reviewed and discarded the “Wheels up on landing check list”. The touchdown was the gentlest I could manage and all was good. I was given the option of hard parking, which I took – I wasn’t that interested in pushing my luck. I shut down the aircraft, took a deep breath in and out and telephoned the flying school. After expressions of support, I was asked if I had checked the panel light switch. I was at this stage on my own and so I rotated the panel switch upwards to max – no change to landing gear lights. Phew, what sort of idiot would you feel if you had declared an emergency because a light switch was at the incorrect setting? At this stage one of the FIs joined me, and turned the panel switch downwards, past a click point, and on came the gear safe lights. I can now tell you how that idiot feels. I then, in a quite fruity and unrestrained manner, expressed my thoughts that it would be a good idea if this manoeuvre of checking panel lights was on the check list. We then looked at the gear RETRACTION check list, which mentions this very point. I had only reviewed the gear lowering check list. As I write (the next day) this doesn’t seem as gormless as it did when I walked back to the flying school

Feeling a little fragile (and gormless) I was much reassured by the supportive attitude of the Head of Training and miscellaneous FIs that were in the office. I took much comfort from the approach of “yes, you could have done something different, but from what you knew at the time, your actions were reasonable”. I will leave agreement or otherwise with that sentiment to readers. I also spoke to an old university friend, who is an immensely experienced professional pilot, who reminded me that there are two sorts of pilots, those that have made mistakes and those that are going to.

Somebody built PA28Rs with the ability to make landing lights so dim they cannot be seen. Who would have thought this? It is in fact a well-known “gotcha”. The reason I had not come across this before was that I had not boarded the aircraft left in this condition before. But this was the first flight after maintenance…be aware that the aircraft (lights/GPS etc) may well not be as you expect. I am sure that somebody at some time, perhaps during night flying, has probably pointed out to me this quirk of the aircraft but, at the time, in the air, I was under pressure and unable to access this knowledge.

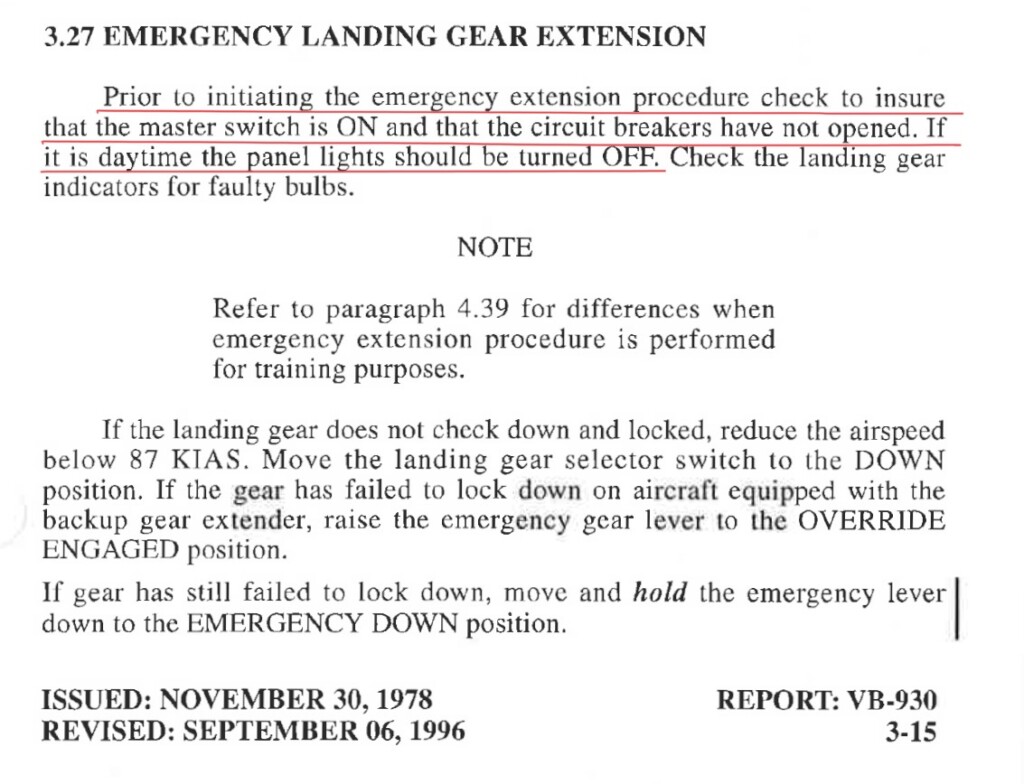

CHIRP Comment

The PA28R undercarriage indication quirk where they are effectively extinguished with the panel lights at anything other than off is a trap that many others have probably fallen into. Why they designed it in such a manner is a mystery, but it’s clearly something that deserves to be publicised widely (both to ATC and pilots) – you don’t know what you don’t know and it shouldn’t be one of those things that only comes to light when old-and-bold pilots pass on the information in circumstances like those reported. Similarly, the fact that the local emergency undercarriage lowering checklist doesn’t mention the light switch seems to be a serious omission. The picture of the POH shows that Piper are aware of the issue and have given guidance (my highlighting) but it may be that this has not translated into local checklists.

Key Issues relating to this report

Dirty Dozen Human Factors

The following ‘Dirty Dozen’ Human Factors elements were a key part of the CHIRP discussions about this report and are intended to provide food for thought when considering aspects that might be pertinent in similar circumstances.

Pressure – focusing on the immediate emergency to the detriment of thinking clearly

Knowledge – information not available in the checklist

Communication – the Piper warning information was not contained in the emergency landing gear extension checklist

This data type is not supported! Please contact the author for help.

The airspace change followed an extensive public consultation from October 2020 to February 2021, which received feedback from more than 2,400 respondents. Therefore, the potential for an airspace change was known about for a substantial period. The announcement by the CAA on 24 November 2021 through aviation forums was expected and it would be reasonable to expect those in the local area to review what had been approved by the CAA between the November announcement and the February implementation. It would appear the reporter did not do this as they were unaware of the announcement.

In addition to the publicity, the date for introducing the additional CAS was aligned with the monthly AIRAC cycle update, which is routine. On Feb 24th the relevant information was incorporated into the respective sections of the UK AIP. The information provided in the response is correct in that when a NOTAM search was conducted in March it would have limited information as the airspace change had been implemented into the UK AIP. It is assumed the reporter did not access the AIC between November and February, probably because they were unaware of the airspace change.

It should be noted the reporter refers to ‘Luton airspace’ on several occasions and concentrates on the Luton aspect of the NOTAM search. In fact, the airspace change was the introduction of Class C airspace and changes to the vertical extent for the Daventry CTA and Clacton CTA. It is true the airspace facilitates arrivals at Luton, but the airspace is not named as ‘Luton’ although Luton was referred to in the publicity. If the reporter had accessed the AIC, the airspace classification and boundaries may have become more apparent. The AIC referred to in the response was still available after Feb 24th.

The suggestion that all changes promulgated by NOTAMs should remain valid until a yearly chart update is impracticable. There is often extensive negative feedback and criticism around the number of NOTAMs provided to a pilot with when planning a flight, with comments such as not relevant or out-of-date. The proposal would make the number of NOTAMs valid before a new chart is published as vast and there would be a lot of negative feedback if this was introduced. It should be noted that electronic flight planning software producers update their products in line with the published AIRAC dates for this purpose.

As an organisation we signpost selected items of aviation news for our membership based on the widest applicability. We strongly encourage members to take personal responsibility for monitoring all other news items that may be relevant to their specific operation. The best and simplest way to do this is via the CAA SkyWise email service. However, we take note of the reporter’s comments, and we shall look at expanding our efforts with regards to airspace consultations in the future.