The Charity

Aviation

Maritime

A very near miss

Initial Report

Outline:

A moment’s thoughtlessness could have had fatal consequences.

What the reporter told us:

A bulk carrier had arrived at a major iron ore terminal and commenced loading without delay the previous evening. At approximately 06:27, loading of No2 hold was completed and the shoreside loader was relocated to the next hold. Moving the loader to No6 hold was completed at 06:36 and the operator confirmed readiness with the chief officer to continue loading.

A few seconds before resumption of loading, the operator observed a crew member in the bottom of No6 hold. The circuit was suspended immediately, and the crew member was ordered to exit the hold by the deck officer on watch. Loading was resumed and completed uneventfully. The captain reported the Near Miss incident to the authorities, as required, and informed the company.

Further Dialogue:

The subsequent investigation noted the following:

From the ship/shore safety checklist review, it was noted that the main communication method between both parties was via handheld radios provided by the terminal on a given channel. It was also agreed that “the ship loader will be informed before access is made to any cargo compartment and that the covers of that compartment will be kept partially closed during the period of such access”.

The chief officer had issued his standing orders for the cargo operation providing, amongst other things, specific precautions to be observed by the crew.

No 6 hold was in ballast condition on arrival, and it was planned to be de-ballasted and then mopped prior to being loaded. Once the de-ballasting was completed, an entry permit was issued at 05:00hrs for two AB’s to enter and carry out the hold wiping.

A Risk Assessment for this operation had been carried out and communicated to the involved personnel. The entry into the hold was being supervised by the bosun. The deck officer on watch was attending to the cargo operations whilst maintaining contact with the chief officer and the terminal.

The work activities of the crewmembers in the cargo hold were completed at 06:30 hrs and both AB’s were ordered to exit. Whilst exiting the space, one AB noticed that his cabin keys had been dropped in the hold and returned immediately to pick them up. Fortunately, the loader operator noticed the AB in the hold and the loading was suspended.

The officer on watch had not given any specific notice to the loader operator to commence or withhold loading operations to No 6 hold whilst he was expecting both AB’s to exit the cargo hold.

From the review of the work/rest hours there was no indication that the involved crewmembers had inadequate rest periods prior to the incident.

Investigation conclusions:

There was no proper notification given by the responsible ship’s personnel to the ship loader in order to delay the shift to the next hold as required by the ship/shore safety checklist (inadequate communication/non-compliance with established safety reporting procedure).

The supervision/control of the enclosed space exit was not adequate since the supervisor failed to see that one of the crew had returned to the hold without obtaining permission. In addition, the AB who returned to the hold to pick up his keys failed to report this to the responsible watch personnel (inadequate implementation of cargo hold entry procedures).

The risk assessment carried out prior to the operation had not adequately identified the hazards related to the entry of personnel in the hold during cargo operations (inadequate risk assessment).

CHIRP comment:

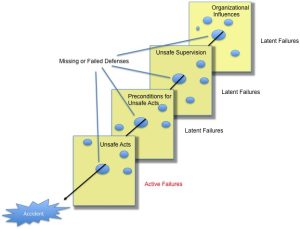

A classic ‘swiss cheese’ incident. There were various checks and precautions either in place or available which should have made this potential accident impossible. One by one they failed because assumptions were made, or possible checks were not followed through and the final hole to line up was a momentary lapse in concentration by an AB who turned back into the hold to recover his dropped cabin key without thinking of the potential consequences. Luckily, the operator of the shore loader noticed the crew member before starting to load the hold. If the ship had kept the No 6 hatch covers partially closed, as required by the ship / shore safety check list during the mopping, it would have been obvious to all parties that the hold was not ready to load.

Swiss Cheese model of breached defences