The Charity

Aviation

Maritime

DUAS xx22

Initial Report

AAIB Report 29860 published September 2024. The UA lost power whilst being flown in an area that excluded the public. This was likely due to the battery becoming detached in flight and it is possible that the battery was not fully latched in place. The same model of battery has been known to swell when it starts to deteriorate, which can compromise its secure retention within the UA. Such swelling can be detected before flight by checking that the battery can sit firmly on a flat surface without rocking, and the operator has highlighted the need for such a check to its pilots.

The flight was the fourth deployment of the UA and was conducted at night in the early hours. The pilot had completed their task and had positioned the UA for the descent when it appeared to lose power and then fell to the ground. The downloaded data abruptly stopped whilst the UA was in the air. Prior to the data loss, the recorded battery health and level of charge were sufficient for continued flight. The battery and UA came to rest some distance apart with the battery still indicating it was powered. The pilot believed they had installed the battery properly but could not be certain.

Both the battery and the UA suffered physical damage, but examination of the plastic battery latching mechanism on both items showed no signs of damage. This lack of damage could indicate that separation did not occur as a result of the impact with the ground.

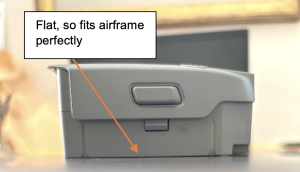

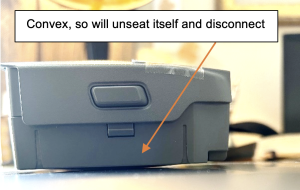

An online search found examples where the same model of battery pack had swelled, and this had compromised the ability of the battery to be securely attached to the UA. An examination of the battery pack after the accident showed that the casing was split, probably as a result of the impact with the ground, but also that there was some evidence of swelling. However, it was not possible to determine whether this swelling was present prior to the accident. If a battery was swollen and had a curved underside surface, this can impede or prevent secure retention of the battery by the latching mechanism.

Following this accident, the UAS operator advised all its pilots of the following:

‘The initial assessment is that the battery either was swollen and or the battery hadn’t completely engaged in the locking mechanism during the build phase. The battery then disconnected and parted with the aircraft when the pilot commenced the landing phase.

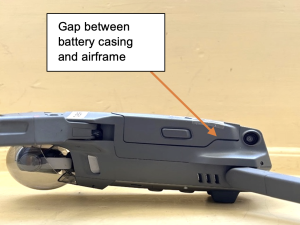

Please be reminded that with any drone, prior to flight, the battery is checked, and you confirm this with a confidence test. (Push pull) and that you photograph or BWV [Body Worn Video] the completed build. Not only from the top but of any locking part and the side view. This should be completed each time you change a battery. NB – Although the locking buttons on the side of the battery should be protruding to indicate locked, as per the photos below if the battery is not sitting flush then even though the buttons are protruding, the battery is not secure.

Below is a photo of what we think happened. Which from looking down on the drone or at night could be missed if rushed.’

This message to its pilots was accompanied by an instruction to report any battery issues to the appropriate person to arrange replacement. The 3 pictures show: the battery not properly secured, but with button positions that could indicate it was if viewed from above; a normal battery with a flat underside; and a battery with evident swelling.

CHIRP Comment

For those readers that have a year or two under their belt flying drones, batteries are a great deal better than they used to be but swelling as they get older has always been something of a potential hazard. If they begin to swell and are then used to fly enthusiastically, they get hot and swell even more. The DJI Mavic 2 batteries have a developing reputation for swelling as they age. If swelling occurs, the battery disconnects itself from the airframe in flight and the motors stop, with the inevitable happening shortly thereafter.

A useful indicator of battery health decreasing, with the potential for swelling to increase, is that flight times start to deteriorate in conditions that are otherwise the same. It’s also worth noting that as the Outside Air Temperature increases, the chance of a battery swelling increases with it, even if it remains within the operating temperature limits set out in the specification. CHIRP’s recommendation is to immediately dispose of any batteries that have begun to swell, and avoid the temptation to tie-wrap, Velcro or tape the batteries onto the airframe. The CHIRP Board discussed at some length whether a recommendation should be made to manufacturers to review the material that batteries are made from and how they lock into place when fitted to an aircraft; we understand that the AAIB has been in touch with DJI regarding this matter but has so far received no response

For those operators who work extensively at night when lighting of the site could be limited, a 3D printed frame that can be passed over the battery to check its shape is perhaps a useful way of verifying whether there is any swelling, and this could be introduced into the pre-flight checks sequence.

Another suggestion is for operators such as emergency services who require instant deployment capability from their equipment, consider having two separate sets of batteries to ensure one set is being deep cycled whilst the other set is always available and ready to go. Keeping batteries fully charged and not deep cycling them often enough will, in the end, accelerate swelling. In addition to this, setting the battery discharge timing in the maintenance App that is being used so that it coincides with shift patterns, might also help with managing deep discharge cycles and readiness. Also, CHIRP recommends that batteries are not stored at full charge, but rather at the manufacturer’s recommended charge levels. Whilst some batteries now have integrated automatic discharge software, some of the earlier aircraft and batteries do not have this capability and so the user should discharge the battery to the correct level, for storage.

Finally, we would strongly suggest that an operator needs to include an aircraft retirement review procedure in its operations manuals. As technology advances there will come a moment when retiring an aircraft will be both appropriate and necessary. Incorporating this into the business plan at the outset will help deal with the issue from a financial perspective.