The Charity

Aviation

Maritime

M2362

Initial Report

Two crew members were onboard during a routine launch of a crew tender in port while the bosun operated the crane from the bridge deck. Following standard procedures, he lowered the tender with the crane fully extended and lifted the hook clear to stow it.

However, the bosun became distracted and inadvertently increased the hoisting speed. The hook struck its stop-stowed position with excessive force, breaking free from its clamped arrangement. The 10kg hook then fell 12 metres, narrowly missing a deckhand by just 20cm before striking the inside of the sponson. The impact sent the hook flying to the side of the boat, causing significant damage to the fairing.

Fortunately, no injuries occurred. The captain’s investigation revealed that the crane’s safety sensor— designed to stop the hook from contacting the job head— was missing. While the crane’s wire remained intact, the lack of this critical safety feature contributed to the incident.

The deck crew received a full debrief to address the near miss, review proper crane operation protocols, and emphasise the importance of functional safety systems. Immediate corrective actions include verifying all safety sensors before operations and reinforcing strict adherence to controlled hoisting speeds.

CHIRP Comment

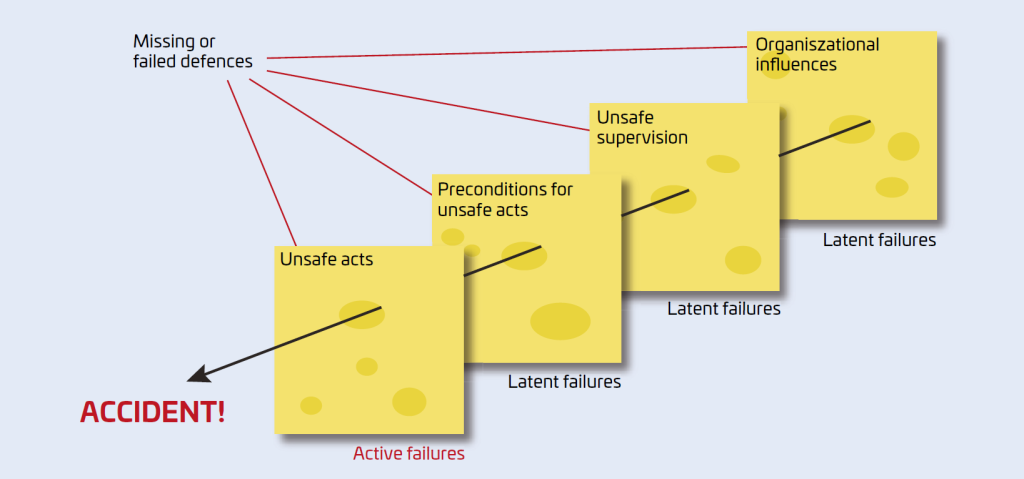

The late Professor James Reason devoted his life’s work to understanding how such failures occur. His Swiss Cheese Model is a potent reminder that accidents are seldom caused by a single error but rather by multiple weaknesses in a system aligning to create the perfect storm. His contributions to safety and human factors will continue to guide industries in preventing incidents like this, ensuring that every barrier is reinforced before disaster strikes.

Key Issues relating to this report

Communication – A replacement was urgently required when the sensor failed or was missing. To prevent its further use, an out-of-service label was also needed. How well do you deal with a critical safety equipment failure?

Distraction – A significant issue in many incident reports. Given the crane’s missing sensor, heightened awareness was demanded while the crane’s hook was stowed. The bosun’s distraction allowed the hook to be stowed in a non-controlled manner, resulting in a situation where a crew member was nearly killed and damage was sustained.

Situational awareness – Everybody involved in the lifting operation should be focused on what is happening. This was a routine tender lifting operation, but the same applies to all lifting operations. Maintaining heightened situational awareness, where you constantly evaluate your status, is demanding and requires teamwork.

Teamwork – Effective teamwork serves as a strong barrier and can prevent the alignment of errors when everyone collaborates.