The Charity

Aviation

Maritime

Mooring incident on an LPG tanker

Initial Report

Outline:

This reporter sent details of an incident that occurred on his ship, a medium sized LPG tanker only 2 years old, which raises some questions about mooring arrangements.

What the reporter told us:

The ship was moored alongside engaged in loading operations, with the deck watchman standing by the manifolds monitoring the ships position. The OOW was in the cargo control room. The watchman reported that the vessel had moved a few metres off the berth and at the same time the OOW noticed the wind had increased from 20 to 30kts. The OOW called the crew to stand by. The loading arms were not disconnected but all crew including the C/O were on deck and the master was on the bridge. The wind eased and the master ordered the crew to use the mooring ropes to bring the ship back alongside – which was done. No injuries were sustained, there was no damage to the vessel or terminal equipment and no pollution occurred.

An onboard investigation was carried out which noted the following:

- The berth in use was more exposed than others in the port.

- The vessel is fitted with soft line mooring ropes throughout whilst similar vessels are equipped with mooring wires.

- The vessel’s length and fairlead positions are not ideally suited for the quayside bollards.

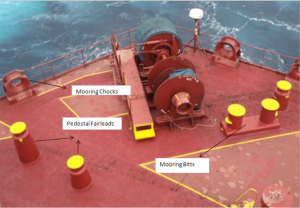

- The vessel is fitted with Panama fairleads throughout which are not best suited for soft lines.

- Mooring ropes on board are a mixture of split drum and loose ropes which turn up on the bitts.

The reporter also noted that similar incidents happened on two subsequent occasions on different voyages.

Further Dialogue:

The excursion limit permitted by the loading arms was not known by the reporter and, while stopping the loading would have been a prudent precaution, it was not stopped on the orders of the captain.

The reporter had been sailing for 11 years on gas carriers and his present ship was the first one with all soft rope moorings, and whilst roller pedestals were fitted to improve the lead of some ropes; all the shipside fairleads were panama chocks.

The scope of the mooring ropes was nominally 60-65m for springs (split drum), 25m for breast lines (turned up) and 50-60m for head and stern lines (split drum).

The results of the shipboard investigation were sent to the company, but the reporter was not aware of any feedback.

CHIRP comment:

A lot of modern ships are built with Panama fairleads (chocks) throughout, which are ideal if used in conjunction with mooring wires but are detrimental to soft mooring lines when compared to roller box fairleads. Equally, some modern ships are designed and built to moor using unrealistic mooring systems. Ports and terminals all over the world invariably demand additional mooring lines which challenge shipboard mooring arrangements – which maybe ill-designed and/or ill-equipped to comply with such demands.

This report highlights many human element issues and learning opportunities not least individual inexperience, vessel familiarisation and SMS procedures. In addition, Mooring Equipment Guidelines 4 published by OCIMF gives invaluable guidance for all types of mooring systems and usage.

Report Ends…………………………..